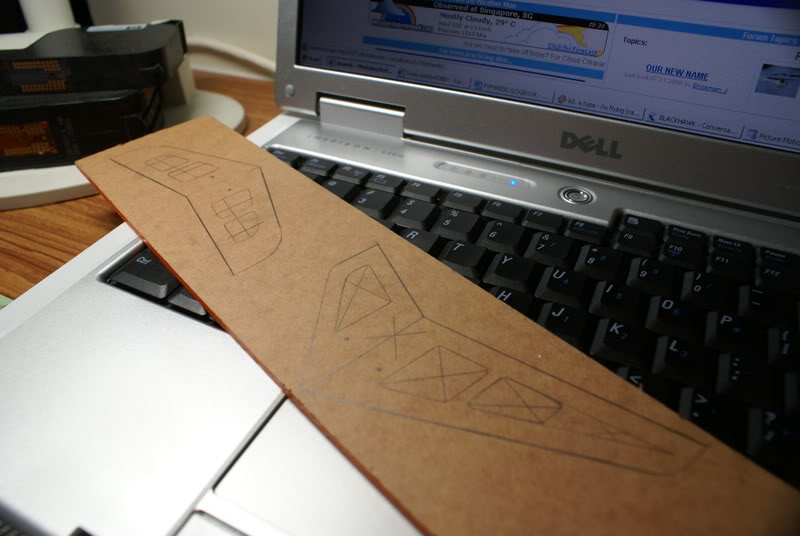

G10 material for Trex chasis

I also not sure leh, you are the only expert I know lor.

I search the web and found this, not sure if this is the right one but looks good.

Based on what I read, G10 is a woven glass fabric epoxy laminate and is used mainly for watch PCB. Maybe it is this:

I also not sure leh, you are the only expert I know lor.

I search the web and found this, not sure if this is the right one but looks good.

Based on what I read, G10 is a woven glass fabric epoxy laminate and is used mainly for watch PCB. Maybe it is this:

Originally posted by skareb1986

Better put a small stone lar

Better put a small stone lar

Ok

Ok

Comment