ok, I am starting a new thread for the building of XL25 racing yacht instead of posting everything under the "materials for making sail" thread...

The plan is available online, FOC, from http://www.xl25.com. It is drawn to scale so you will have to use something like Photoshop to cut it up; print on A4 paper and then tape them back together.

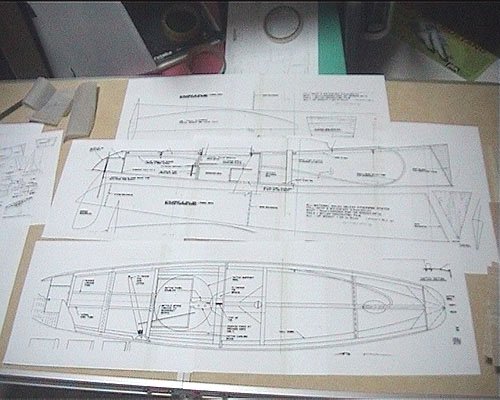

Here's an overview of the "taped-back" plan, ready for use:

The plan is available online, FOC, from http://www.xl25.com. It is drawn to scale so you will have to use something like Photoshop to cut it up; print on A4 paper and then tape them back together.

Here's an overview of the "taped-back" plan, ready for use:

) it's a lot lighter.

) it's a lot lighter.

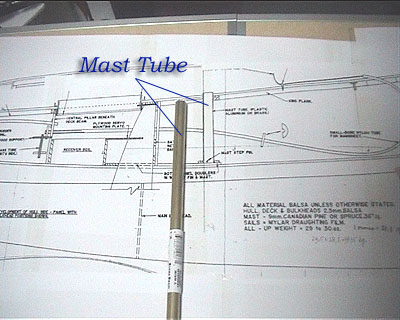

...i can send u a zip (about 1.5Mb) containing 13 tif files which are cut- ups of the big plan. all u need to do is to print each one on A4 papers then tape them together.

...i can send u a zip (about 1.5Mb) containing 13 tif files which are cut- ups of the big plan. all u need to do is to print each one on A4 papers then tape them together.

Comment