Hi all,

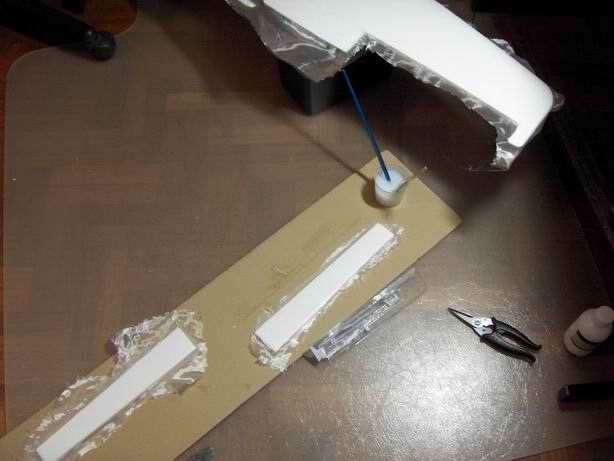

I'll explain in detail the glassing process that i use. Did this a couple of months ago, as such have limited photos of the process. A friend and myself would be glad to glass one of your planes and do a good documentation. Will be more than happy to answer any questions. Ok, here goes..

I'll explain in detail the glassing process that i use. Did this a couple of months ago, as such have limited photos of the process. A friend and myself would be glad to glass one of your planes and do a good documentation. Will be more than happy to answer any questions. Ok, here goes..

Comment