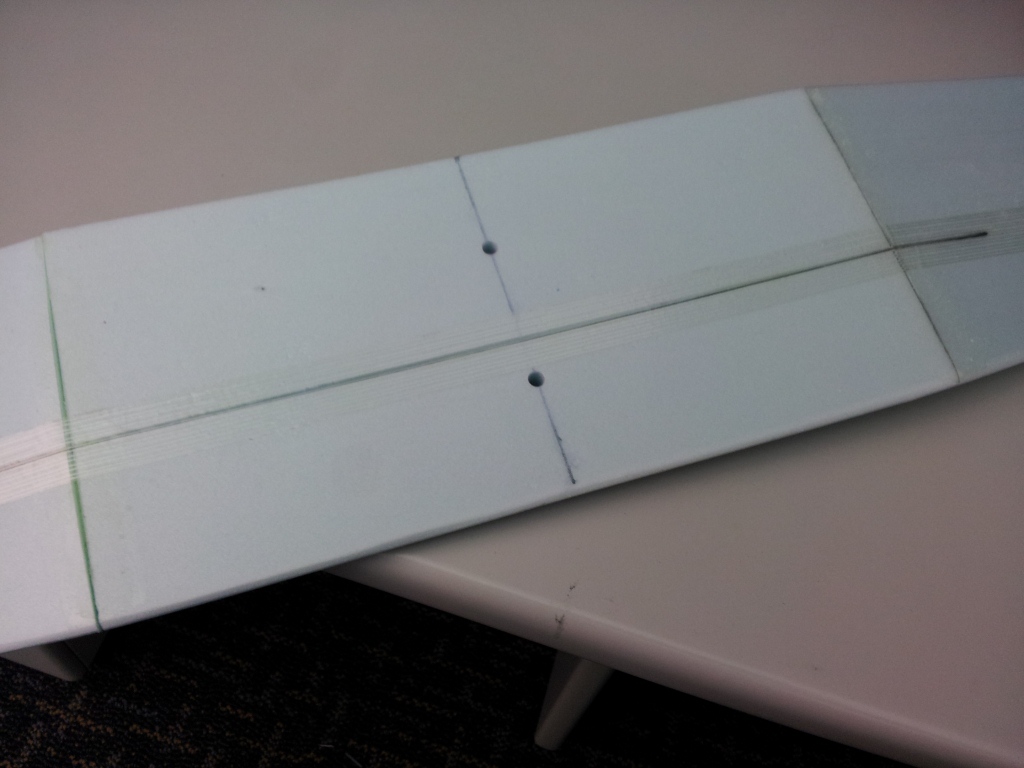

The following pictures are taken from a scrap foam for illustration purpose, and as such, the tailboom access is absence in these pictures.

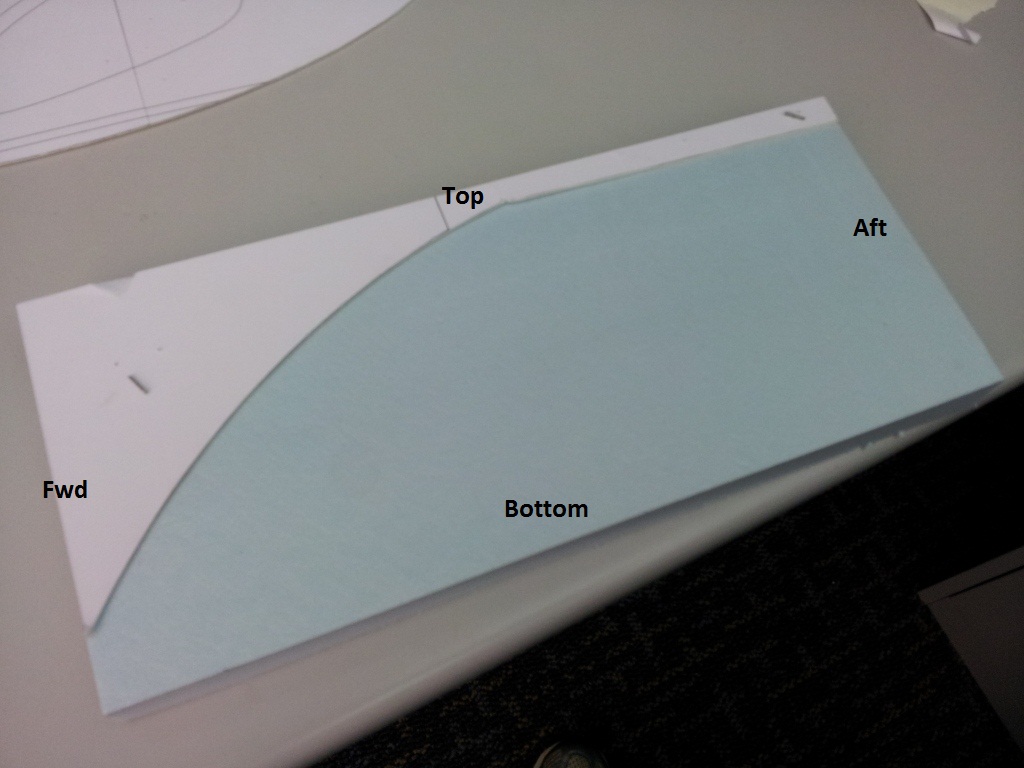

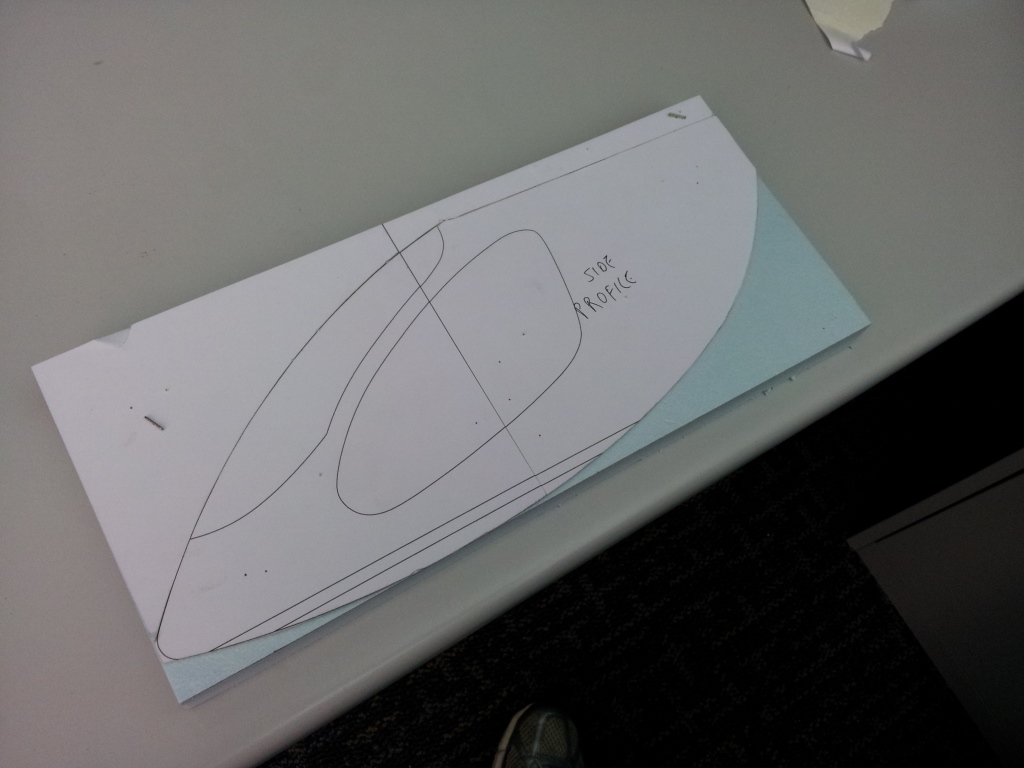

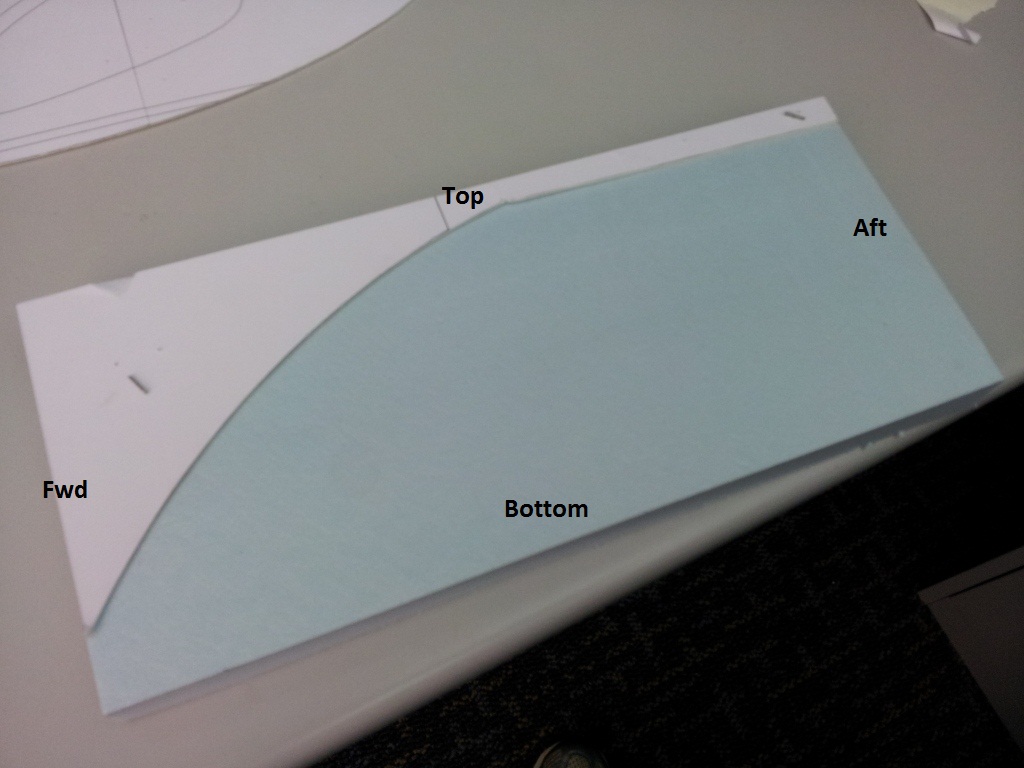

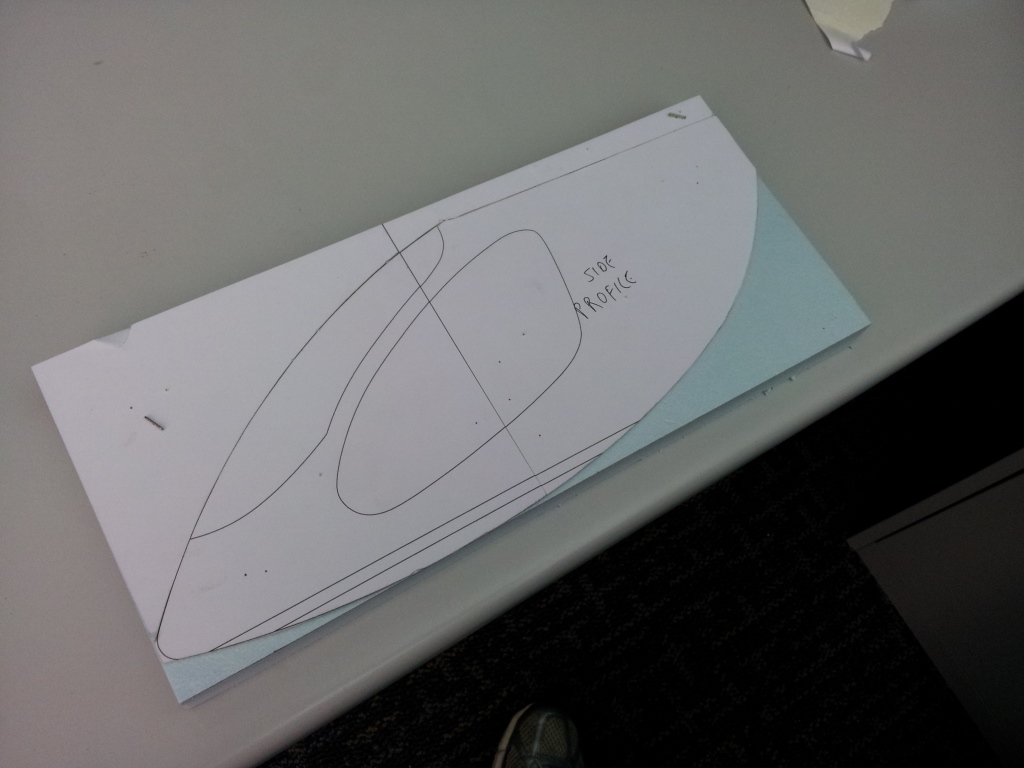

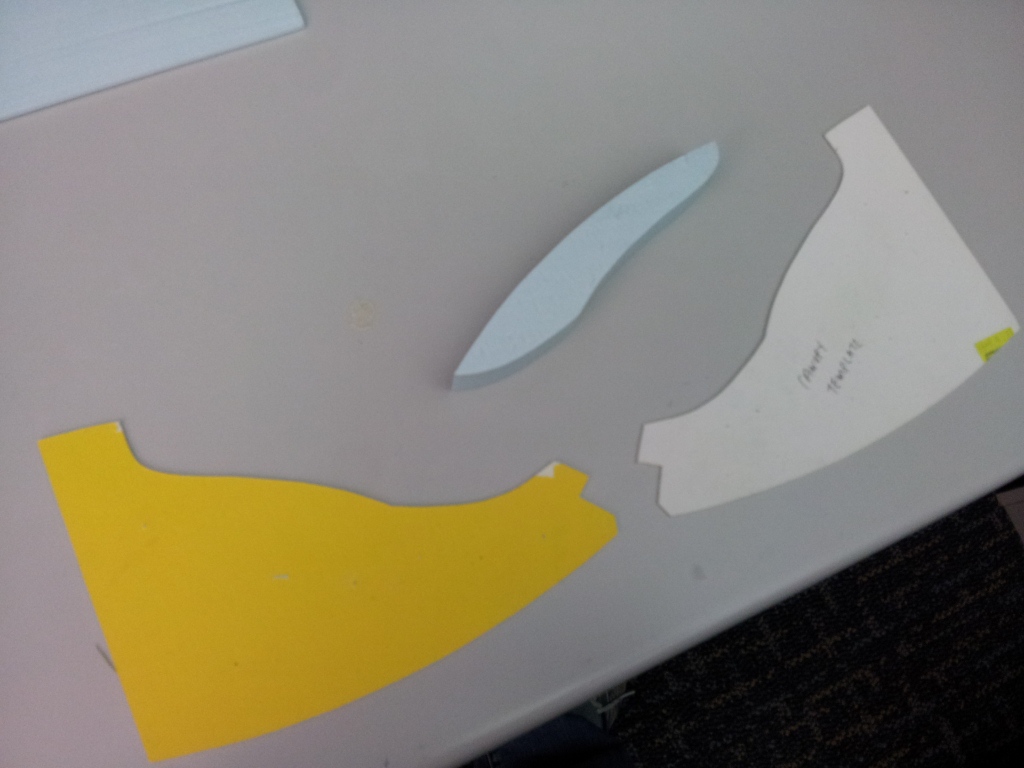

Once the tailboom recess is done, pin the fuselage pod template jig on the upper edge of the block. It is not a template itself, but just a jig to pre-position the curvy shaped fuselage template. Next, place the fuselage pod side profile template against the jig, and either pin it onto the foam or use a light spray of 3M spray adhesive. Then, unpin and remove the jig.

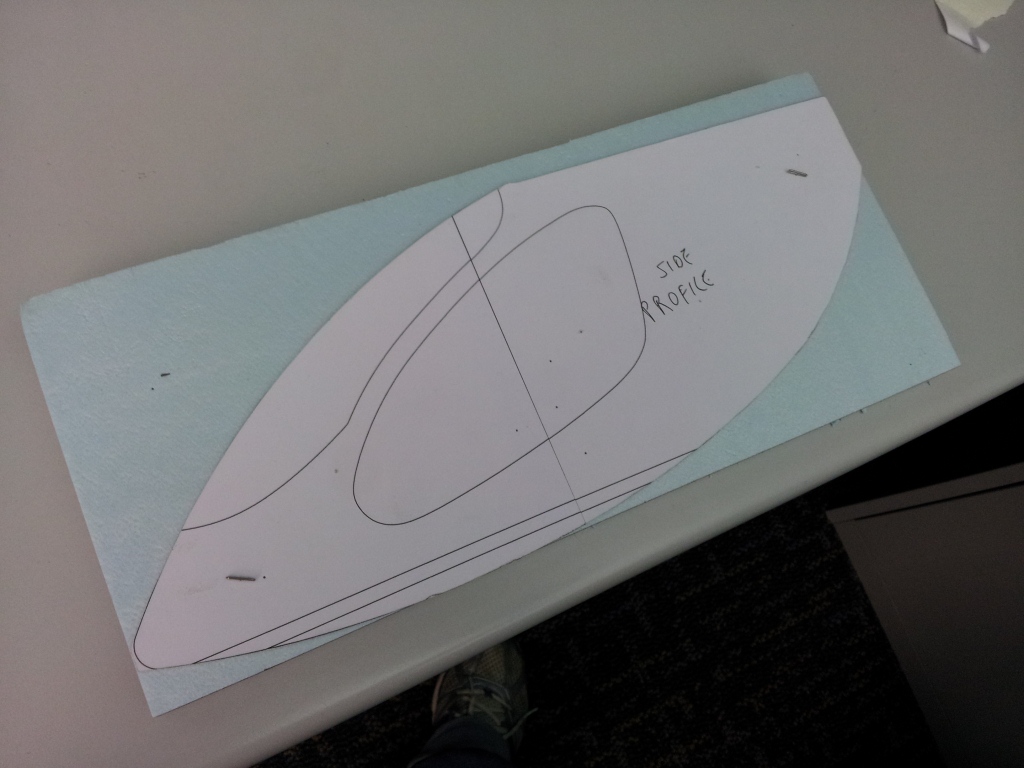

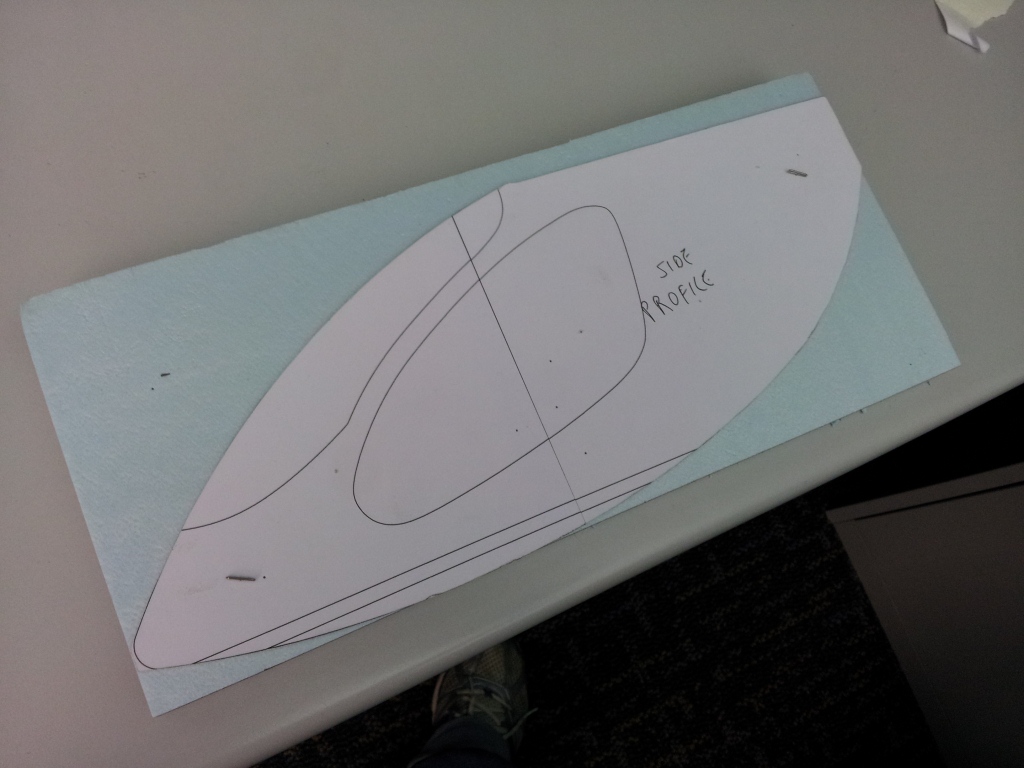

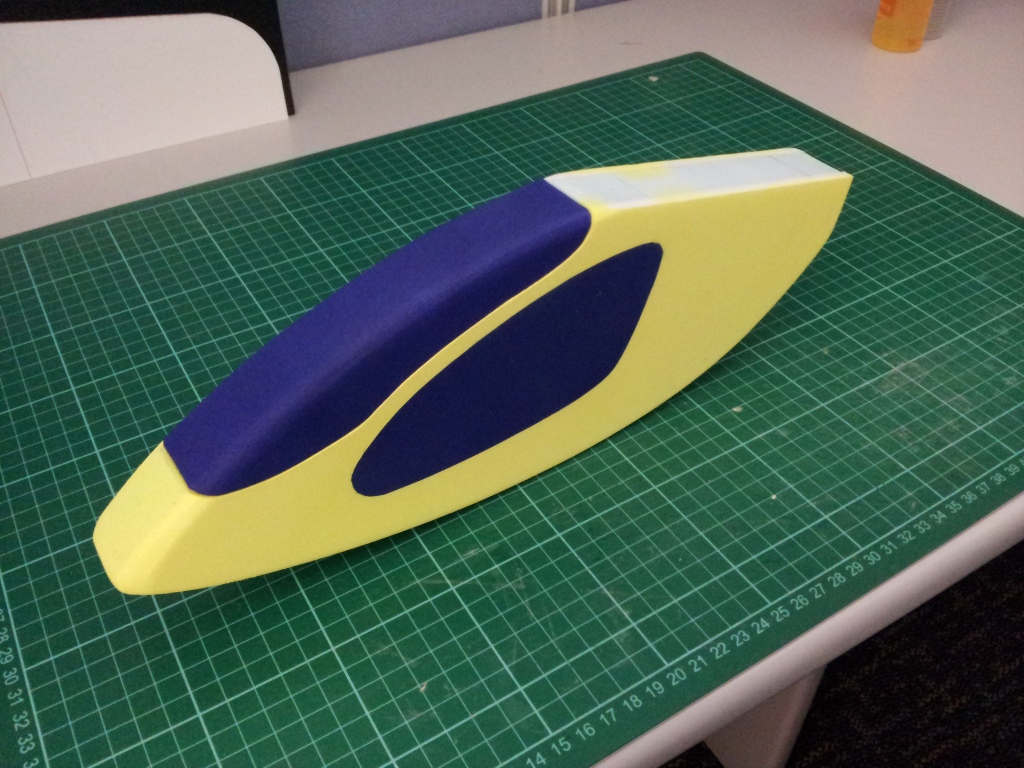

Do the same on the opposite side of the foam block and make sure that both templates sits correctly and thier positions coincide with each other before hotwire cutting out the fuselage pod core.

Once the tailboom recess is done, pin the fuselage pod template jig on the upper edge of the block. It is not a template itself, but just a jig to pre-position the curvy shaped fuselage template. Next, place the fuselage pod side profile template against the jig, and either pin it onto the foam or use a light spray of 3M spray adhesive. Then, unpin and remove the jig.

Do the same on the opposite side of the foam block and make sure that both templates sits correctly and thier positions coincide with each other before hotwire cutting out the fuselage pod core.

Comment