It came to my understanding in seperate occasions that some RC folks have different definition of 'scratchbuilding'. In one occasion, a shop owner told me that buying a Mountain models P-51 balsa plane kit will require 'scratchbuilding' to get it flying. On another occasion, someone claimed that he had scratchbuilt a Topsky 2.0 before it was being sold to a nice gentleman.

While I didn't really challenge the 2 individuals who made the remarks, most folks who has been in this hobby for quite a while, would understand that 'scratchbuilding' does involve a lot more than just building from a commercially available kit, and usually requires the builder to fabricate most, if not all of the airplane strustural components from raw materials. Don't take me as an elitist, but it's been know around the world that RC plane scratchbuilding is literally building a model plane with raw materials and plans, since the very first day of aeromodelling.

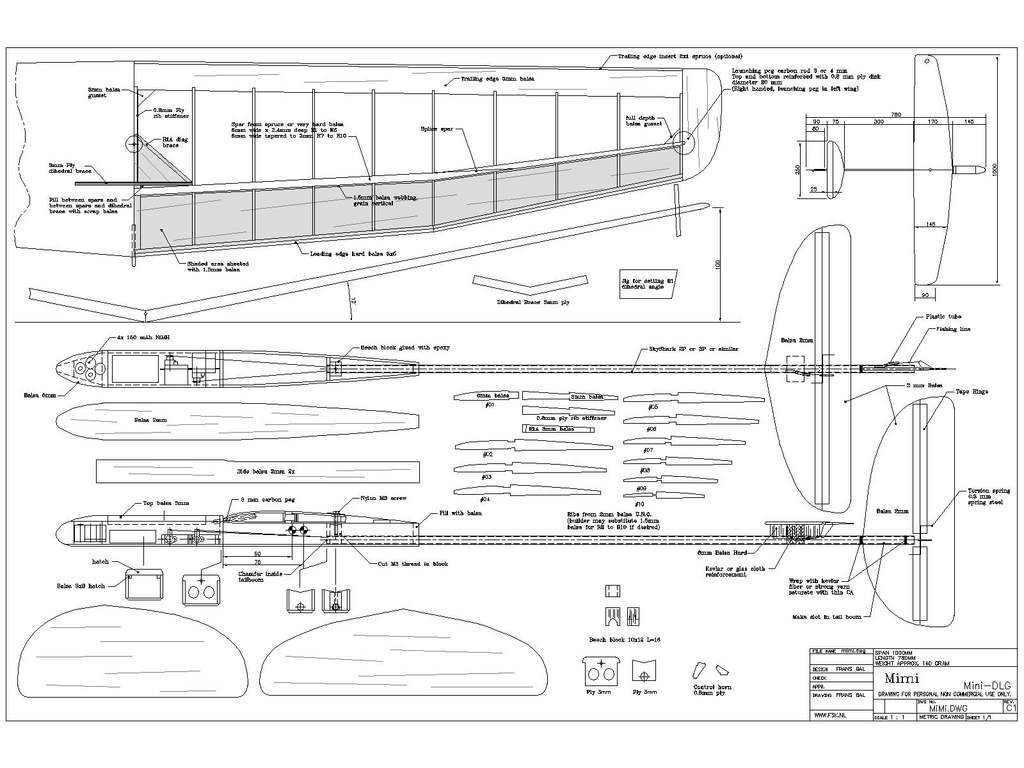

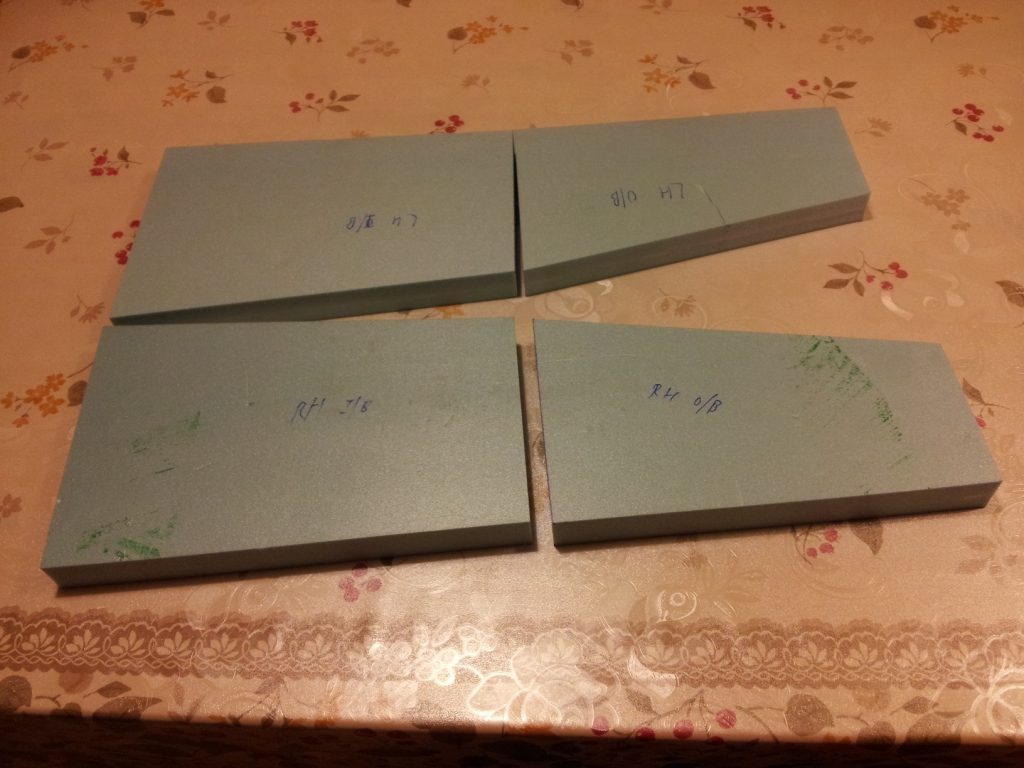

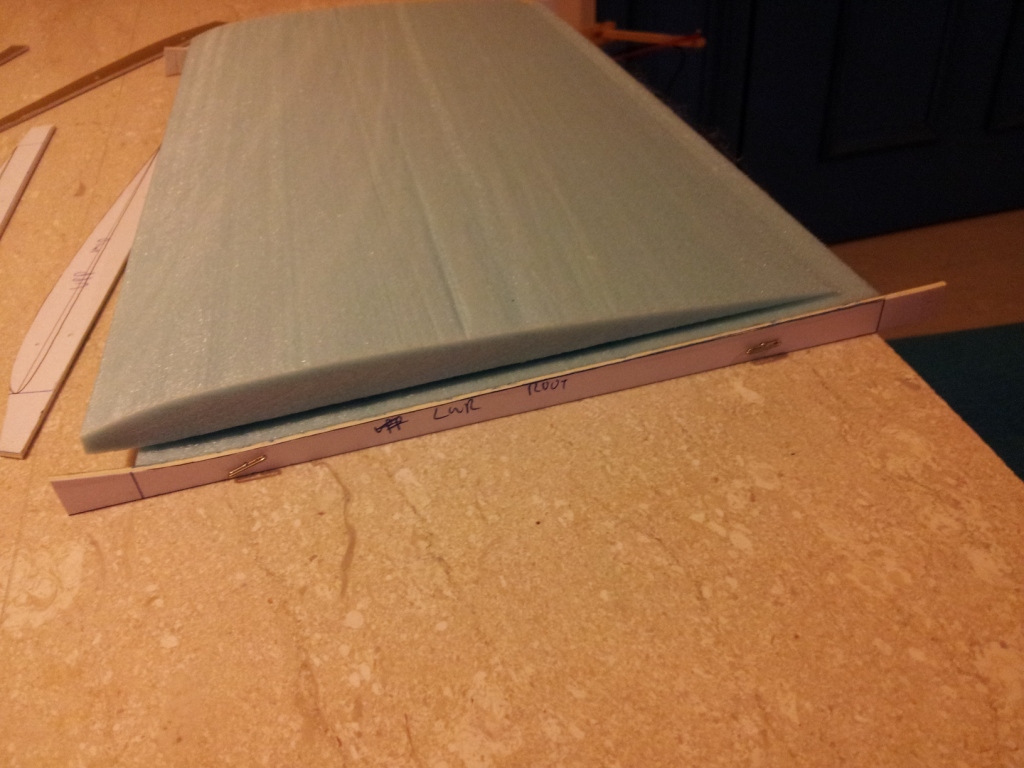

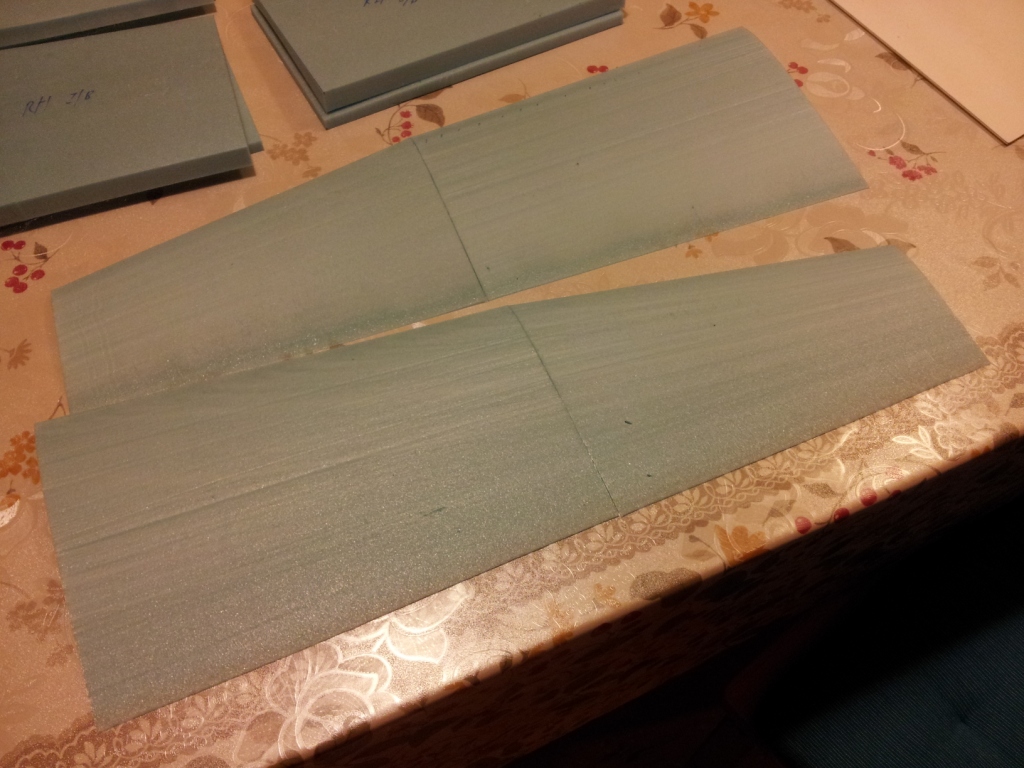

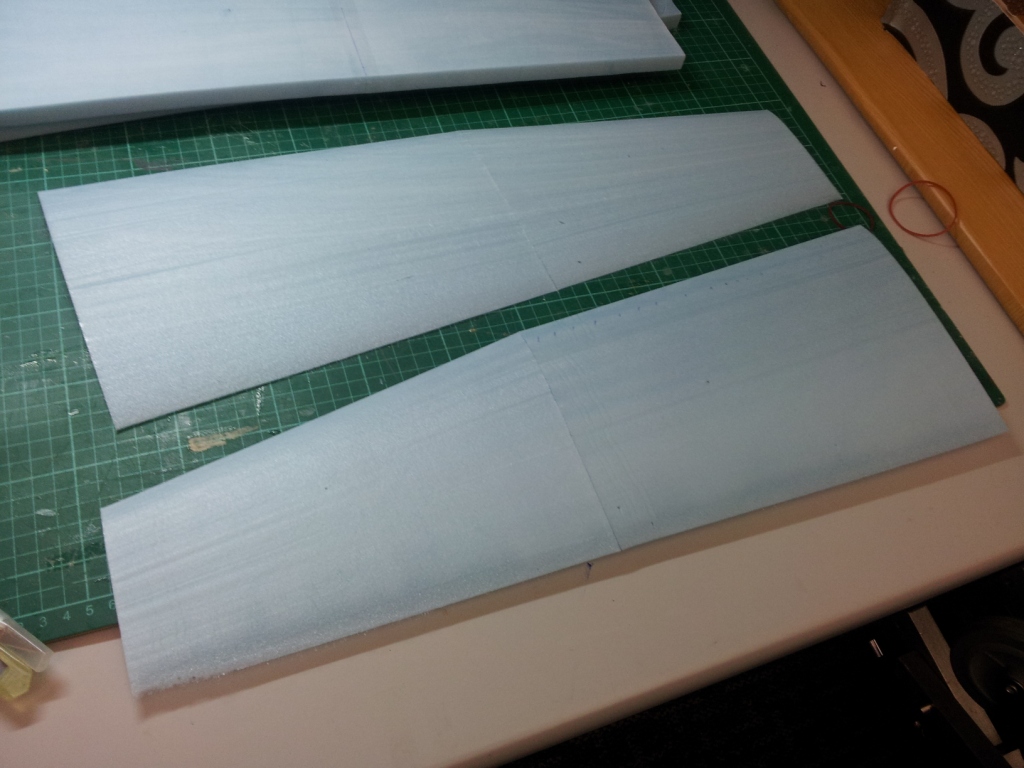

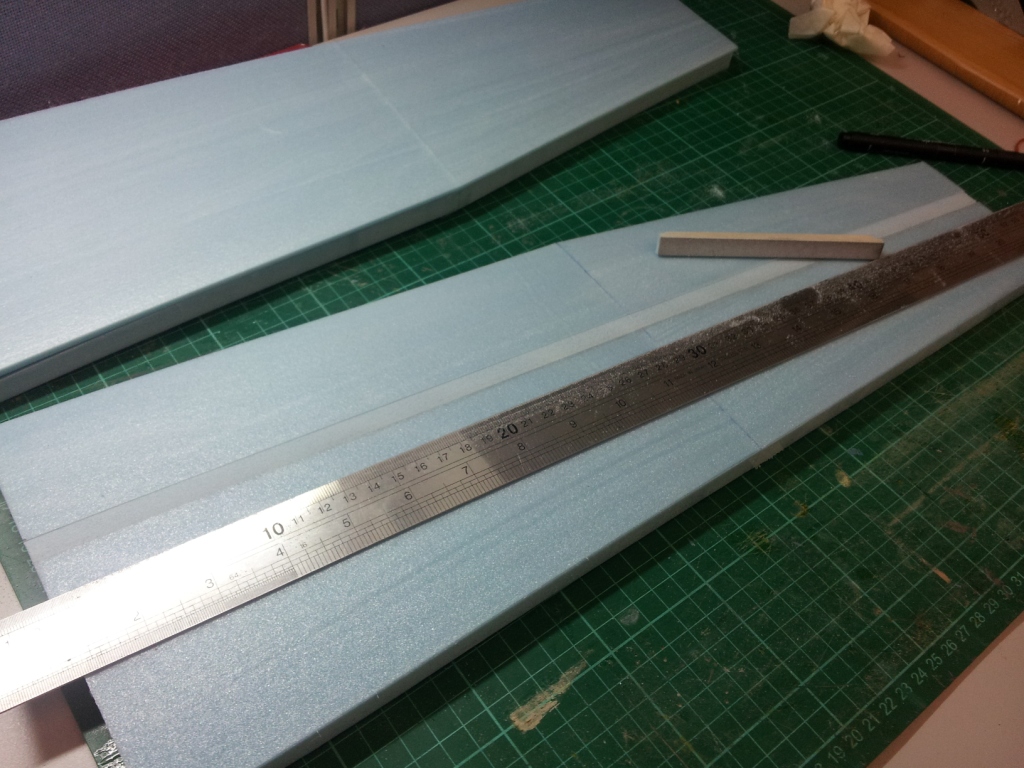

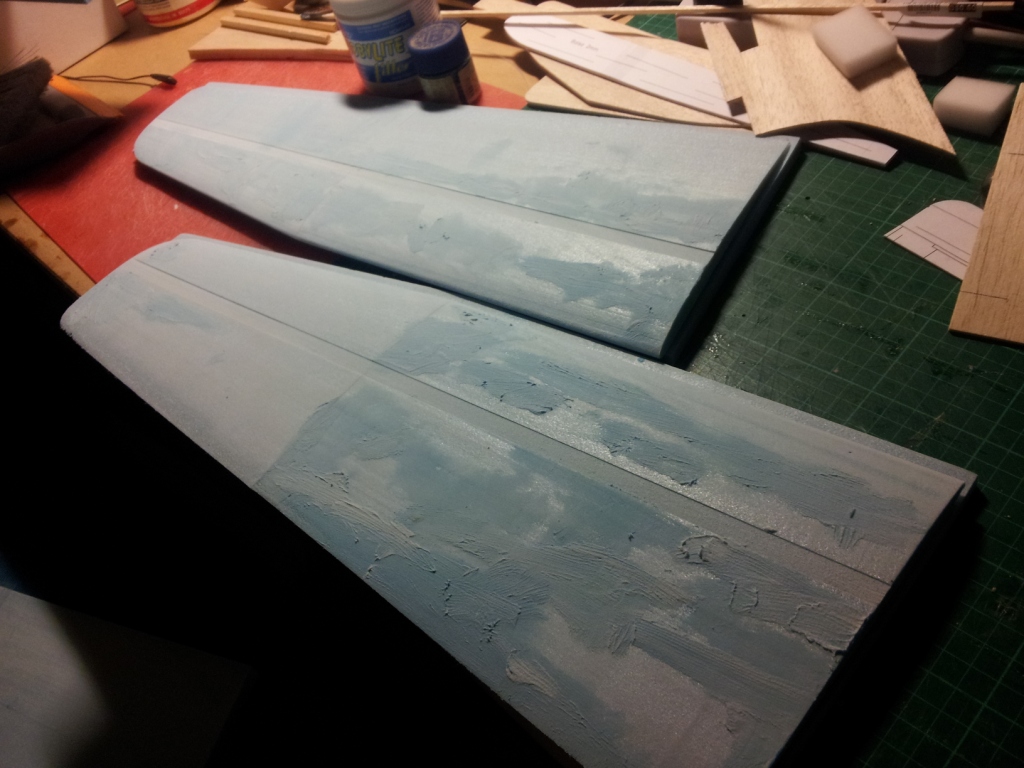

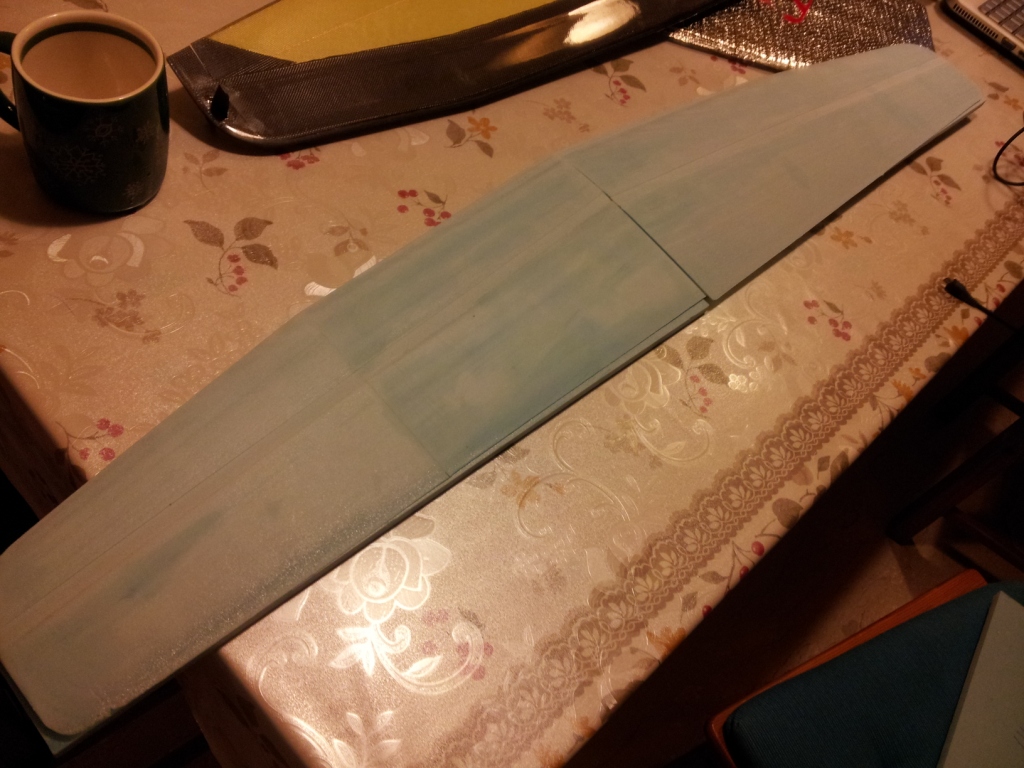

Since I am currently building a DLG, this thread may come in handy as it serves to provide the readers the real sense of scratchbuilding a Discus Launched Glider.

While I didn't really challenge the 2 individuals who made the remarks, most folks who has been in this hobby for quite a while, would understand that 'scratchbuilding' does involve a lot more than just building from a commercially available kit, and usually requires the builder to fabricate most, if not all of the airplane strustural components from raw materials. Don't take me as an elitist, but it's been know around the world that RC plane scratchbuilding is literally building a model plane with raw materials and plans, since the very first day of aeromodelling.

Since I am currently building a DLG, this thread may come in handy as it serves to provide the readers the real sense of scratchbuilding a Discus Launched Glider.

Comment