Hello everyone,

I could not resist and got myself a "Supersonic Lobster".

A short description of the kit:

- Printed and cut 3mm depron foam

- Ply wood dowels to strengthen the fuselage and rudder

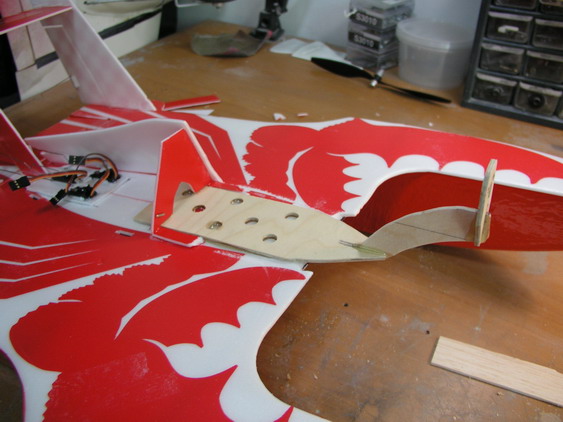

- Plywood motor mount (not 100% sure how this works that's why I designed my own as you will see later)

- Decals

- Clear vac formed canopy

- hinge tape

- music wire pushrods

- control horns

What do you need to complete the kit:

- Foam save CA

- Uhu Por (I only used CA as I could not get the Uhu Por - was not the best choice)

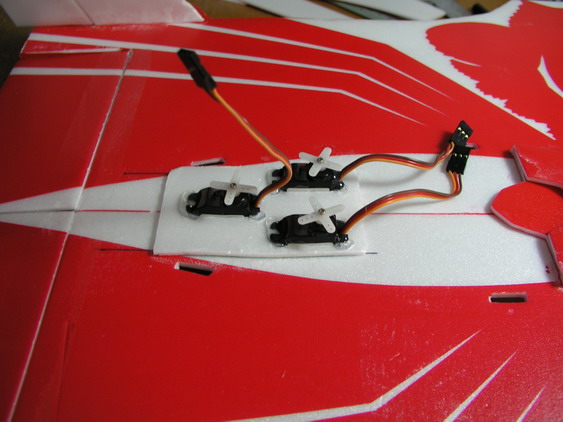

- 3 servos (HS-55)

- 4 channel receiver

- Battery (I use a 3S1P 1200mA pack)

- Radio with delta mixing

- Brushless motor, esc and 8x4 prop

- 30min Epoxy for the motor mount

- 3mm ply for the motor mount (only if you do your own mount design like I did)

- 3mm Carbon rod (in case you do not want to use the supplied wood dowel)

- 5mm hollow carbon tube (in case you do not want to use the supplied wood dowel)

This is how it should look like when finished:

I could not resist and got myself a "Supersonic Lobster".

A short description of the kit:

- Printed and cut 3mm depron foam

- Ply wood dowels to strengthen the fuselage and rudder

- Plywood motor mount (not 100% sure how this works that's why I designed my own as you will see later)

- Decals

- Clear vac formed canopy

- hinge tape

- music wire pushrods

- control horns

What do you need to complete the kit:

- Foam save CA

- Uhu Por (I only used CA as I could not get the Uhu Por - was not the best choice)

- 3 servos (HS-55)

- 4 channel receiver

- Battery (I use a 3S1P 1200mA pack)

- Radio with delta mixing

- Brushless motor, esc and 8x4 prop

- 30min Epoxy for the motor mount

- 3mm ply for the motor mount (only if you do your own mount design like I did)

- 3mm Carbon rod (in case you do not want to use the supplied wood dowel)

- 5mm hollow carbon tube (in case you do not want to use the supplied wood dowel)

This is how it should look like when finished:

: Do NOT use masking tape. Yes it hold the parts nicely together but upon removal it will also strip your Lobster of some of his color

: Do NOT use masking tape. Yes it hold the parts nicely together but upon removal it will also strip your Lobster of some of his color

...i love seafood....

...i love seafood....

Comment