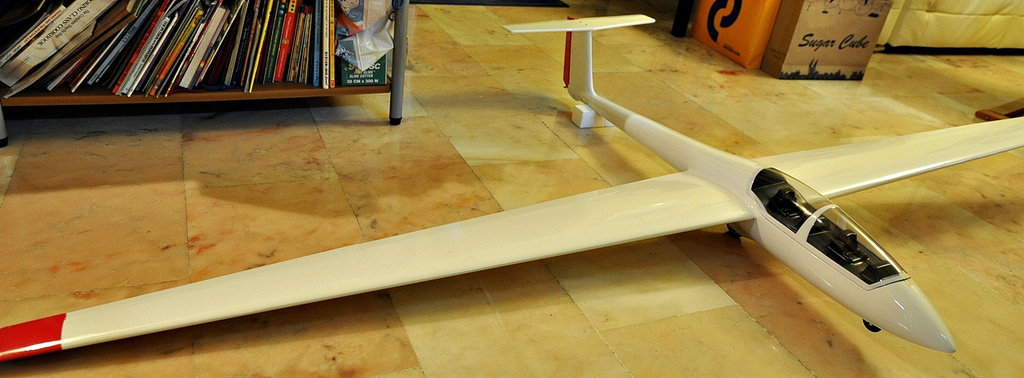

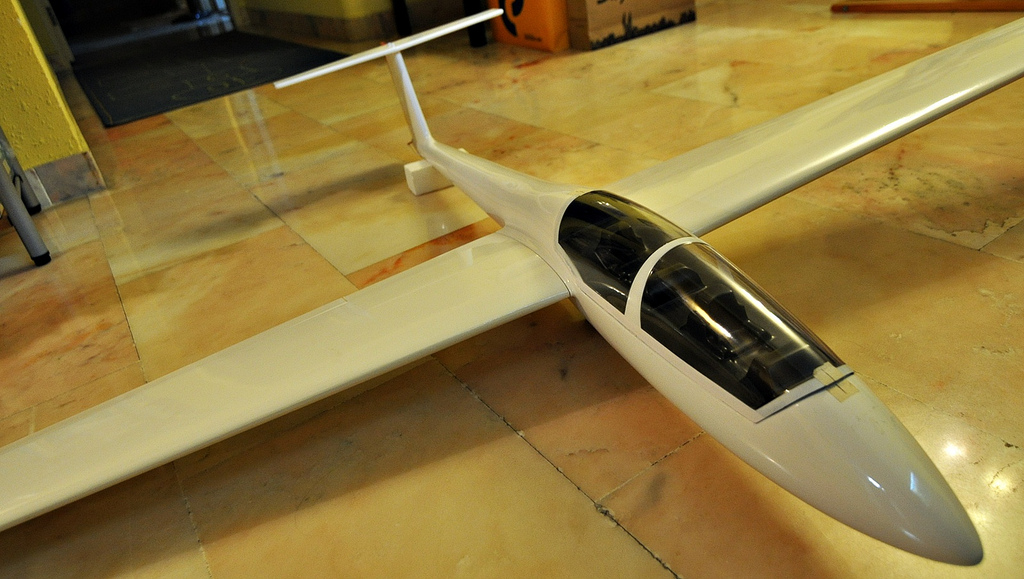

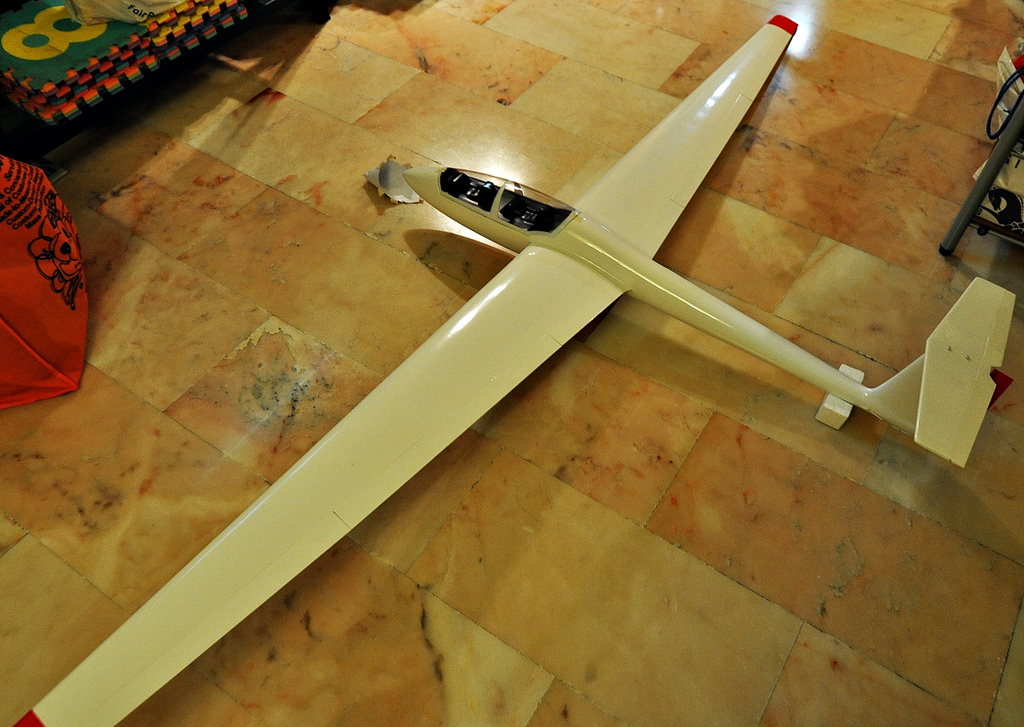

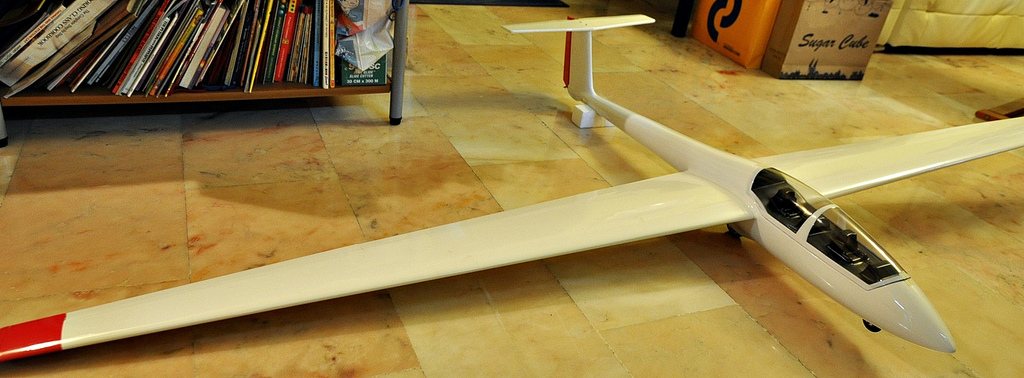

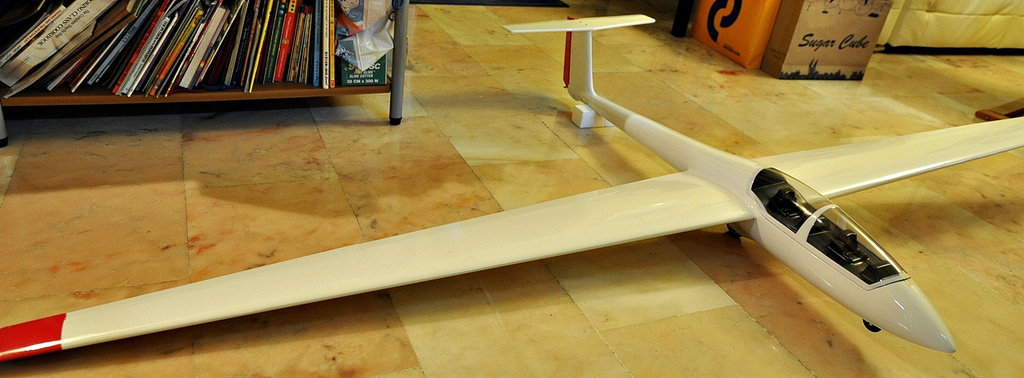

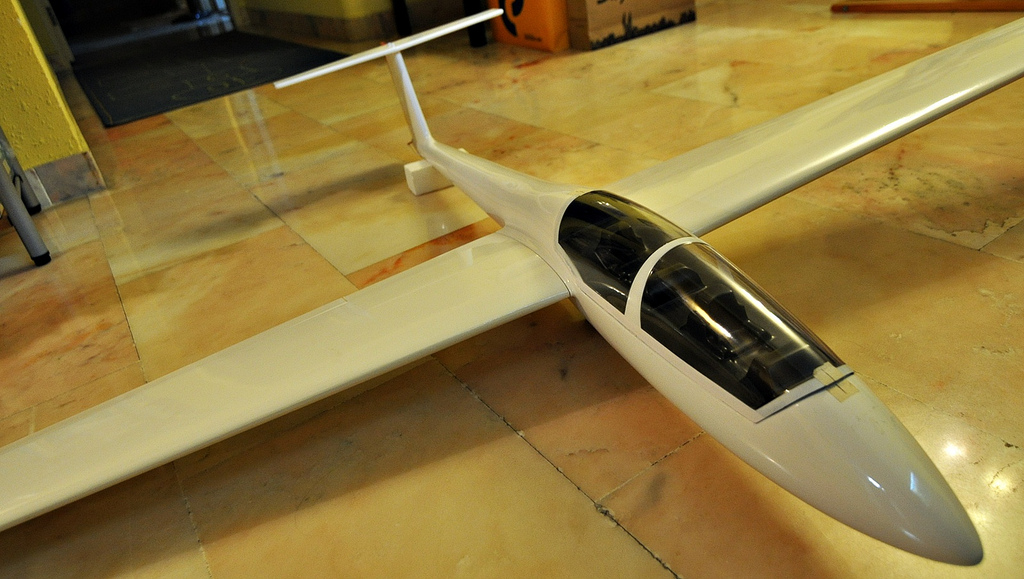

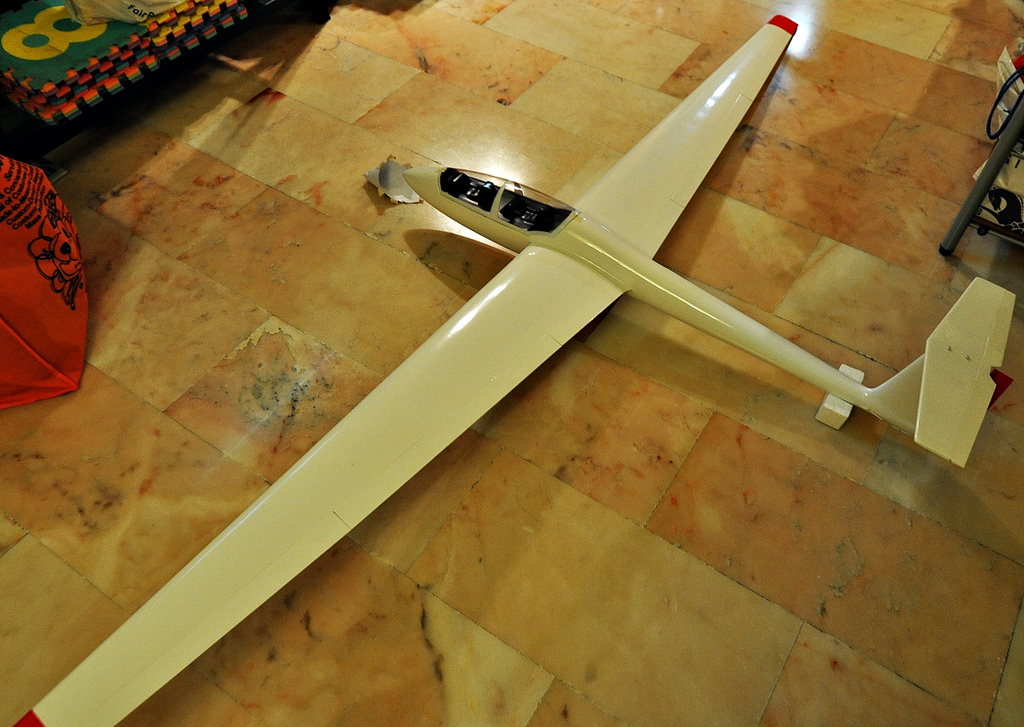

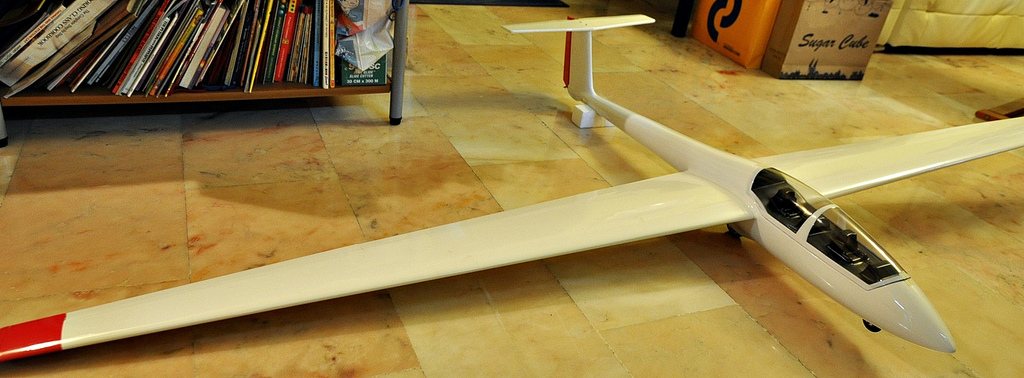

Bought this glider 2 years ago from China while I was on a working trip there. I started to assemble the glider about 2 months ago, this is almost completed. Left with the canopy hold down.

I made a little modification to the positioning of the elevator servo. I choose to put the servo up front, in order to save the overall weight of the glider. Still need to seal up the elevator cut-out on the stabilizer.

I have not document the build thread, as my build is consistent. Having the put aside the build for other priorities. I will write up a build review later.

Here are some pictures of the 90% completed build.

I made a little modification to the positioning of the elevator servo. I choose to put the servo up front, in order to save the overall weight of the glider. Still need to seal up the elevator cut-out on the stabilizer.

I have not document the build thread, as my build is consistent. Having the put aside the build for other priorities. I will write up a build review later.

Here are some pictures of the 90% completed build.

Comment