Been thinking about doing up a bigger pylon racer than the Deceiver / Swindler series by Joe Yap.

In theory, it is upsized to 1m wingspan.

started work today.

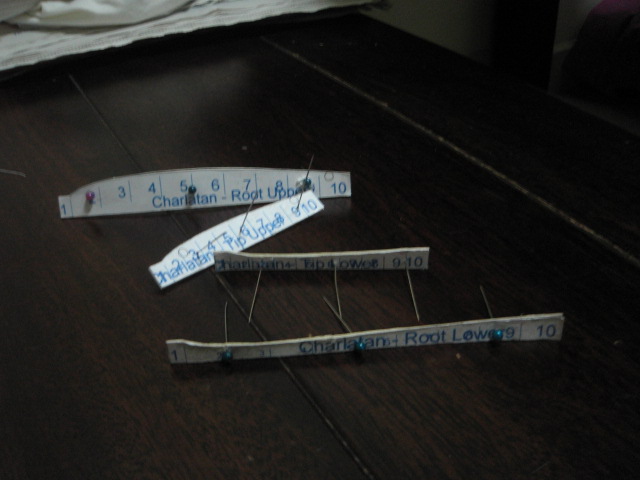

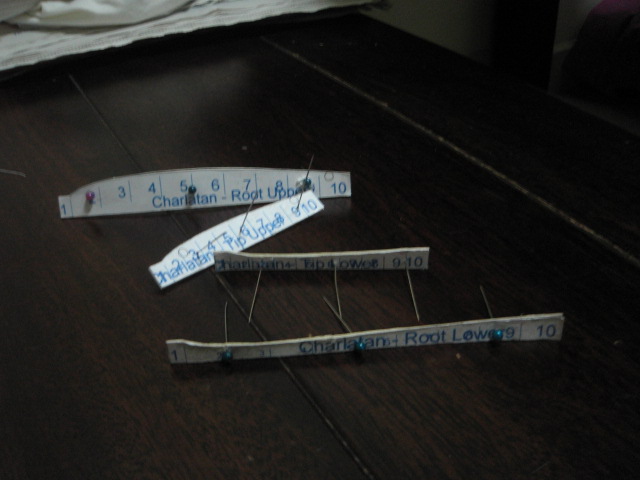

Generated templates from Profili.

Powered up the ol' cutting bow and wire

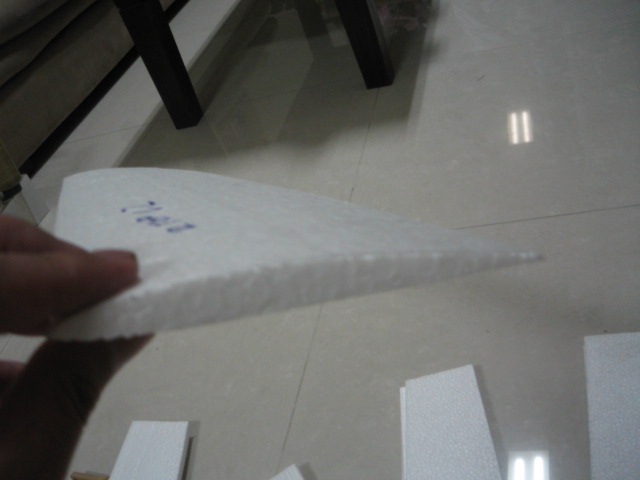

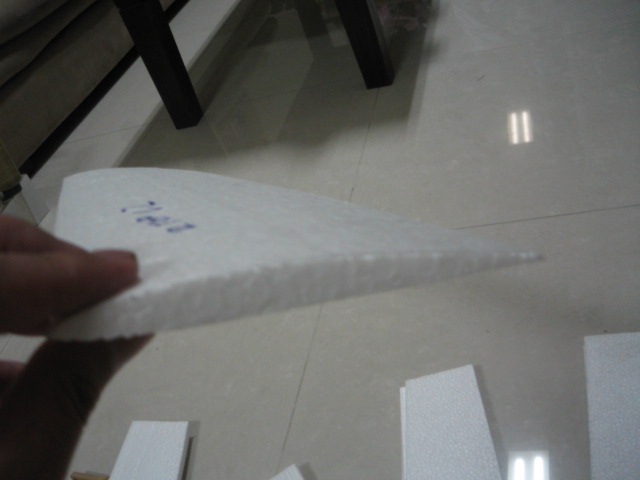

Cut myself out 4 (3 in picture) wing shapes

Later on, cut out airfoils

Probably still looking through the designs, I got them on Google Sketchup.

In theory, it is upsized to 1m wingspan.

started work today.

Generated templates from Profili.

Powered up the ol' cutting bow and wire

Cut myself out 4 (3 in picture) wing shapes

Later on, cut out airfoils

Probably still looking through the designs, I got them on Google Sketchup.

Comment