To be frank, I was never too fancy over the Super Blanik L23 look over the years. I was facinated by the modern class composite scale gliders. Only during the recent years, I came across some detailed 3-views of the older built-up wooden and metal gliders that enticed me to design and build the Pilatus B-4, which I love a lot.

During the last few months, I have been aerotowing small sport and semi-scale gliders with my Freedom 20 tug and I thought of trying it out with my semi-scale Swift S-1. However, it is designed primarily as a slope soarer and with the higher wingloading and ever-growing trees planted along the PFW, I feel that I'll need a much lighter glider for the job. Not just that it'll be easier to be towed, it should be light enough for thermalling, I hope.

I always wanted to thermal a scale glider from aerotow but most commercial small scale gliders are pretty hopeless on thermalling due to thier higher wingloadings. The faster and cheaper production methods resulted in rather heavy airframes, which is better suited for slope.

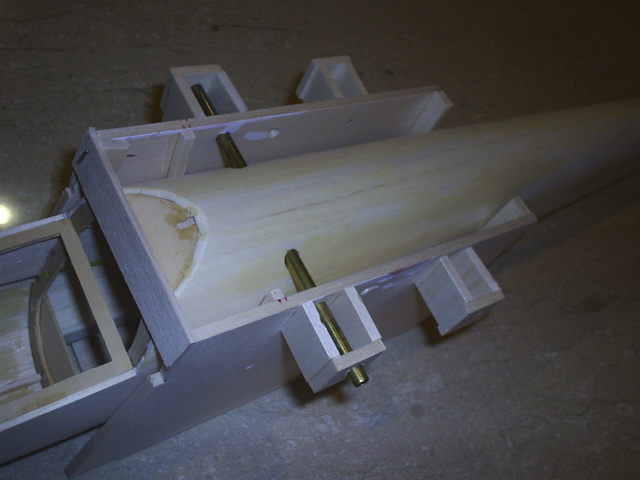

I want a lightweight small scale glider with aerotow release fitting and preferbly fix undercarriages as such it'll be aerotowed anytime. I also want it to be relatively quick build so that it'll not disrupt my B-29 build for too long. So I was searching for a good subject with lots of straightlines in the airframe which I can adopt conventional balsa built-up construction with the lightest possible airframe. I remembered the Super Blanik with has a straight forward fuselage section and simple tapered wings. The only special feature is that it has forward swept wings, but this does not pose much challenge for the build.

I quickly drafted the plans out to determine the final size, which pretty much depends on the lengths of the available raw materials. I ended up at 76" full span, which the longest single member in the wings and fuselage is exactly 36" long.

During the last few months, I have been aerotowing small sport and semi-scale gliders with my Freedom 20 tug and I thought of trying it out with my semi-scale Swift S-1. However, it is designed primarily as a slope soarer and with the higher wingloading and ever-growing trees planted along the PFW, I feel that I'll need a much lighter glider for the job. Not just that it'll be easier to be towed, it should be light enough for thermalling, I hope.

I always wanted to thermal a scale glider from aerotow but most commercial small scale gliders are pretty hopeless on thermalling due to thier higher wingloadings. The faster and cheaper production methods resulted in rather heavy airframes, which is better suited for slope.

I want a lightweight small scale glider with aerotow release fitting and preferbly fix undercarriages as such it'll be aerotowed anytime. I also want it to be relatively quick build so that it'll not disrupt my B-29 build for too long. So I was searching for a good subject with lots of straightlines in the airframe which I can adopt conventional balsa built-up construction with the lightest possible airframe. I remembered the Super Blanik with has a straight forward fuselage section and simple tapered wings. The only special feature is that it has forward swept wings, but this does not pose much challenge for the build.

I quickly drafted the plans out to determine the final size, which pretty much depends on the lengths of the available raw materials. I ended up at 76" full span, which the longest single member in the wings and fuselage is exactly 36" long.

...You're building at LIGHTSPEED ! ...compared to me

...You're building at LIGHTSPEED ! ...compared to me  ...I'm still struggling to find time to finish up my Talon.

...I'm still struggling to find time to finish up my Talon.

Comment