This is not the first time. Before the Southwest monsoon season starts, our good friend Mr Tee, "poloso'ed" me to build something for the Phuket slope soaring season. Last year, it was the JART. This year, he stumbled across the 'Padawan' micro slope soarer from RCG in search of a pitcheron plane, and managed to convince me and Johnnie Wong to build it.

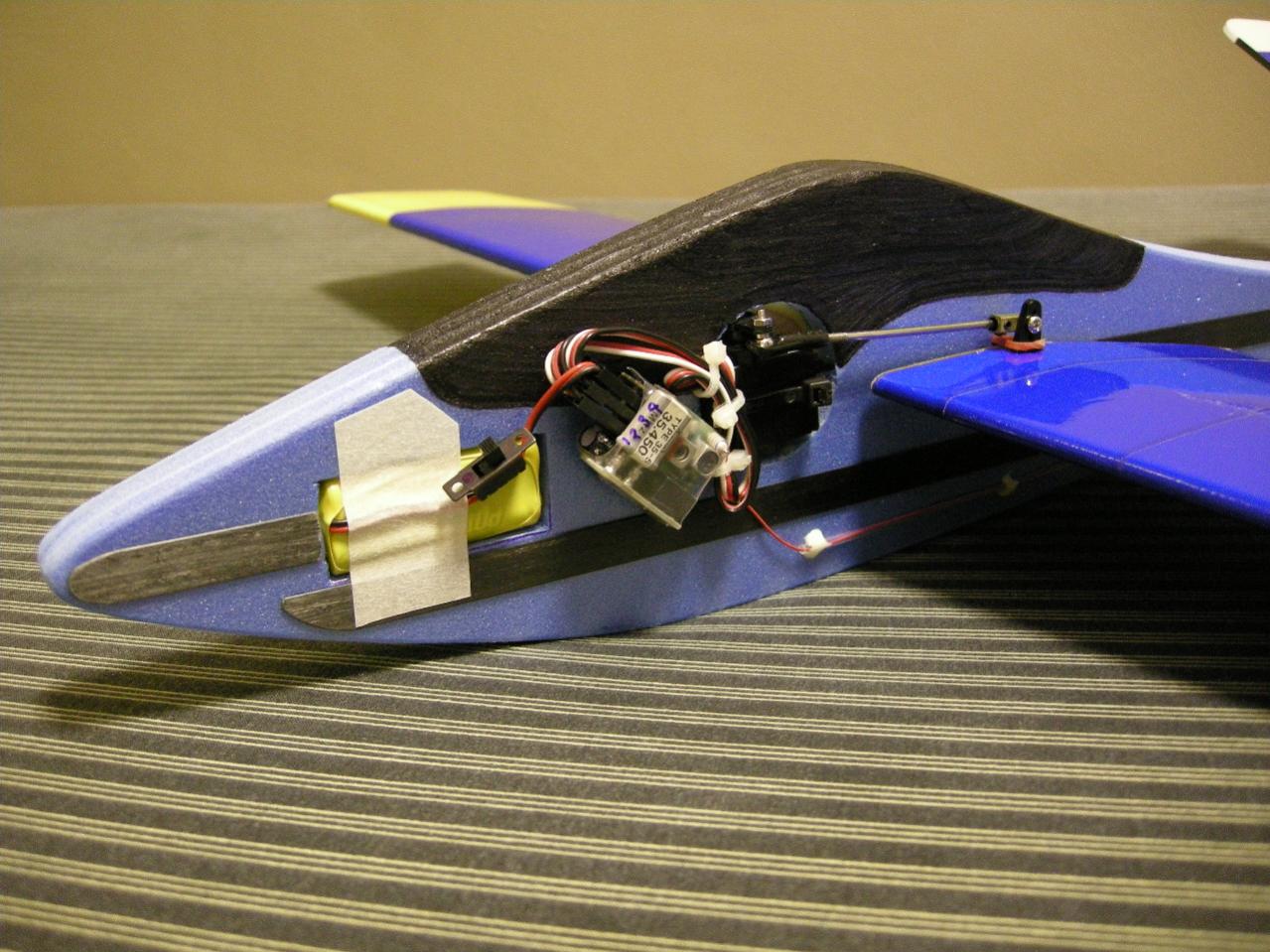

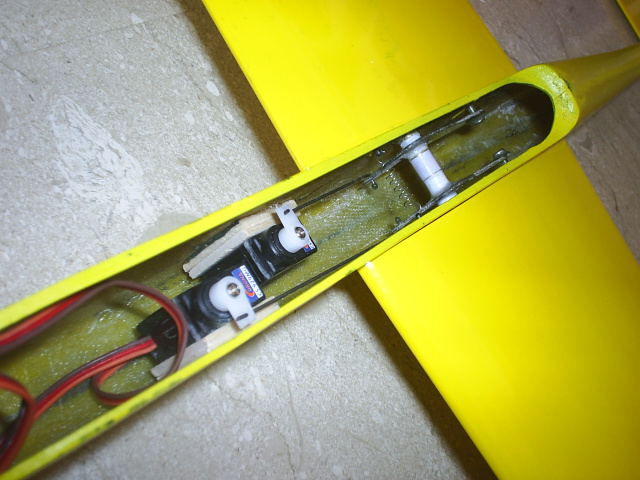

A little on the original model. The designer built it with EPP foam and the model is rather small at about 32" of total wingspan. The model uses 2 servos to drive the variable pitch main wings directly. The horizontal stabilizer is, as the name implies, just a stabilizer, no elevator. Both pitch and roll controls are done by changing the angle of incidence of each wing. The original has no rudder control.

See link: http://www.rcgroups.com/forums/showthread.php?t=820994

These are some pictures of the original design.

A little on the original model. The designer built it with EPP foam and the model is rather small at about 32" of total wingspan. The model uses 2 servos to drive the variable pitch main wings directly. The horizontal stabilizer is, as the name implies, just a stabilizer, no elevator. Both pitch and roll controls are done by changing the angle of incidence of each wing. The original has no rudder control.

See link: http://www.rcgroups.com/forums/showthread.php?t=820994

These are some pictures of the original design.

Comment