Hi guys,

I am currently slowly repairing my plane's damaged wing after months of collecting dust

Most of the repairs are straight forward but for one of the section, I am not too sure of the best way to go about repairing it.

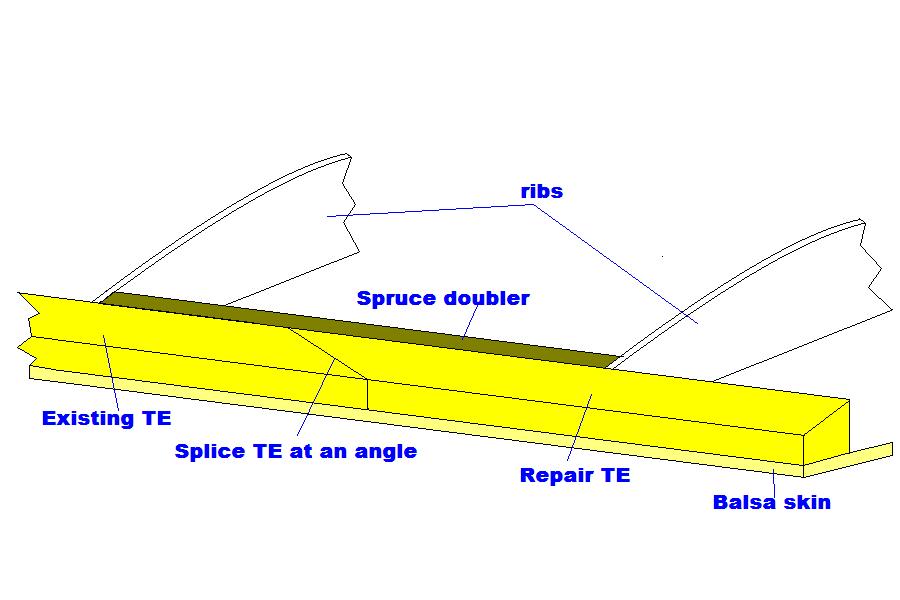

The section in question is the wing bolt area. The bolt ripped through the hole. From the pictures I attached, the area is built out of a wedged section of balsa running the whole length of the TE of the wing.

It seems like a high stress area so I am wondering if I can just cut a small section where the hole is and replace it by a new section and still be strong enough...

OR

do I need to replace the whole length of the "wedged" piece of balsa?

Thanks,

Fit

I am currently slowly repairing my plane's damaged wing after months of collecting dust

Most of the repairs are straight forward but for one of the section, I am not too sure of the best way to go about repairing it.

The section in question is the wing bolt area. The bolt ripped through the hole. From the pictures I attached, the area is built out of a wedged section of balsa running the whole length of the TE of the wing.

It seems like a high stress area so I am wondering if I can just cut a small section where the hole is and replace it by a new section and still be strong enough...

OR

do I need to replace the whole length of the "wedged" piece of balsa?

Thanks,

Fit

) to over lap the glued in TE balsa stock on the top. Overlay by at least 1/2" on all 3 sides (less the TE) and use expoxy for this.

) to over lap the glued in TE balsa stock on the top. Overlay by at least 1/2" on all 3 sides (less the TE) and use expoxy for this.

Comment