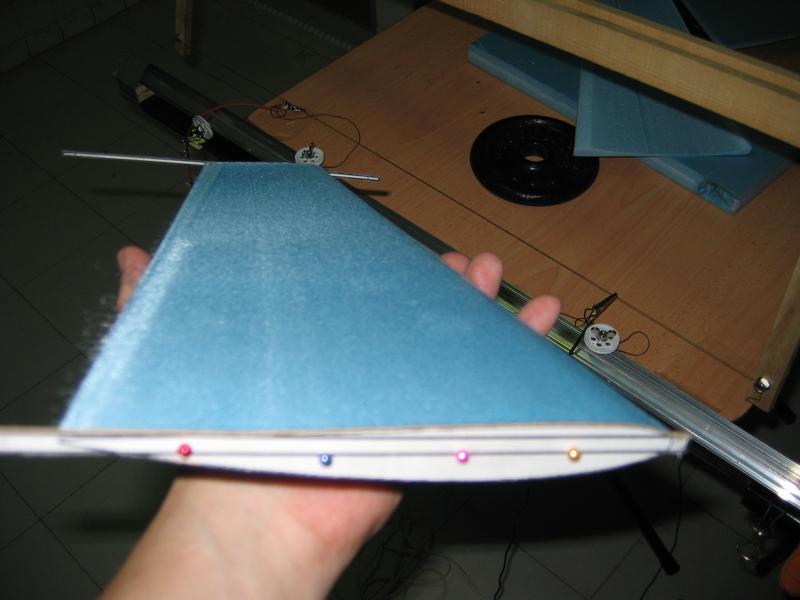

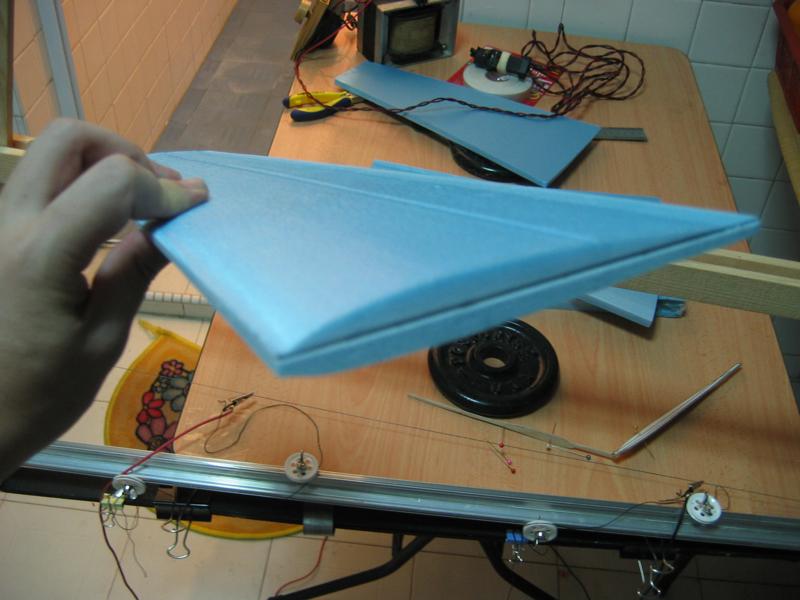

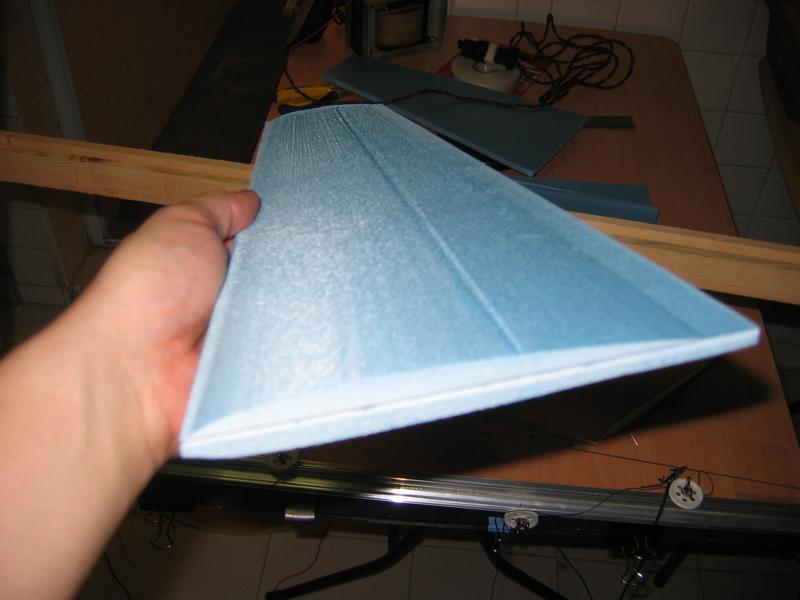

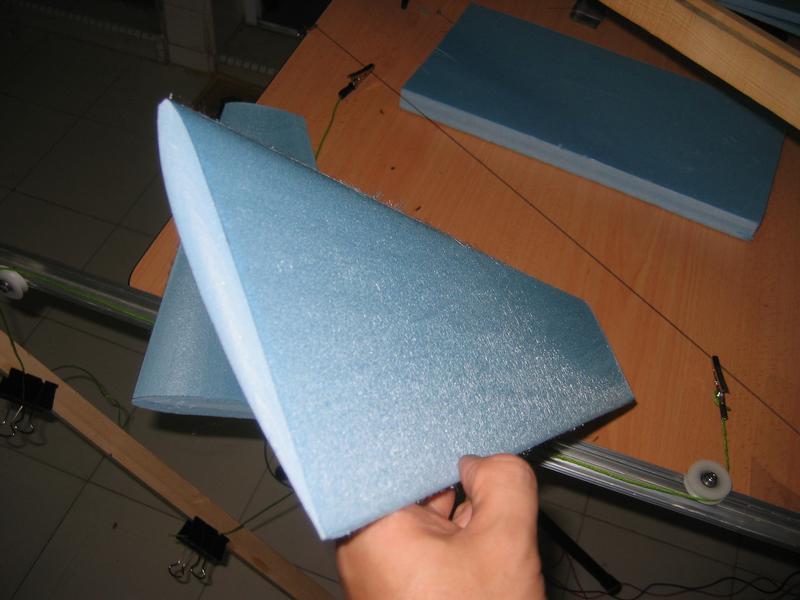

Yes I finally did it! I have successfully replicated the gravity assisted foam hot wire cutter capable of cutting tapered wings! Here are the pictures from my very first cut! You will notice that the top surface of the wing has a bad hot groove, that was caused by the bad templates I have, the hot wire was cutting very smoothly until it got caught by an uneven ridge on the template.

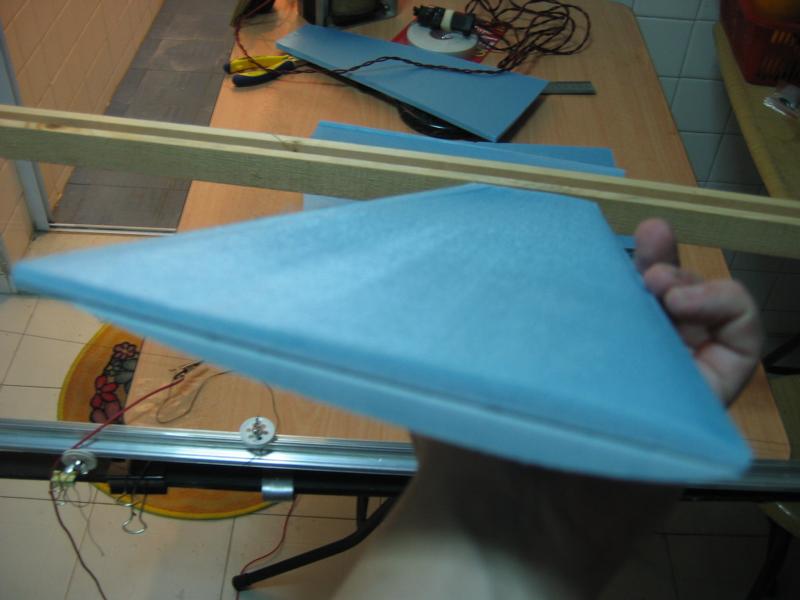

Yes I finally did it! I have successfully replicated the gravity assisted foam hot wire cutter capable of cutting tapered wings! Here are the pictures from my very first cut! You will notice that the top surface of the wing has a bad hot groove, that was caused by the bad templates I have, the hot wire was cutting very smoothly until it got caught by an uneven ridge on the template.The bottom cut was perfect! Now I'm using a much lower hot wire temperature to cut than my previous manual method. The resulting surface is much better than cutting manually! This is fantastic! And I didn't spend a fortune on building this device. It took me a few hours to figure out how to cut the taper and adjust the weights though, but when I finally did, the first cut was almost flawless.

My design differed from the Feathercut system in that my hot wire bow is suspended like the Utah Flyers Organization's version. http://www.utahflyers.org/ (check out the video on foam cutting! Simply amazing!)

Now all I need to do is to find out where I can buy formica sheets as this is the recommended material for making airfoil templates.

It may be crude in construction but the most important thing is that IT WORKS!

, it was already 4am by the time I posted the pictures

, it was already 4am by the time I posted the pictures  . The initial results are very promising and I believe I can tweak the set up further to get even better results. So far the only stumbling block are the airfoil templates, I need to ensure that they are super smooth so that the hot wire can slide over them smoothly and easily. The hot wire temperature can also be lowered further to reduce the shrinkage near the wing tip for tapered wings, and the benefit of having a variometer is that I can manually adjust the temperature on the fly during the cut. The current swing arm is cobbled from strips of old balsa wood, I need to make my way down to the timber wholesaler (at the junction of Jalan Syed Alwi and Townshend Road) and buy wood from their waste basket to make a better and more robust swing arm.

. The initial results are very promising and I believe I can tweak the set up further to get even better results. So far the only stumbling block are the airfoil templates, I need to ensure that they are super smooth so that the hot wire can slide over them smoothly and easily. The hot wire temperature can also be lowered further to reduce the shrinkage near the wing tip for tapered wings, and the benefit of having a variometer is that I can manually adjust the temperature on the fly during the cut. The current swing arm is cobbled from strips of old balsa wood, I need to make my way down to the timber wholesaler (at the junction of Jalan Syed Alwi and Townshend Road) and buy wood from their waste basket to make a better and more robust swing arm.

Comment