Now that I gotten the Pilot Zero type 22 ready for her maiden flight, I can get on with what I've been itching to build - the Sig Four Start 120. The power plant for it will this little (well not so little) gem from MVVS. With the pipe it'll be an overkill but a 3rd party sports exhaust from Bison is going to set me back US$95 so I'll stick with the pipe for now.

The MVVS IFS 26 is a petrol engine. Runs on 40:1 gasoline (95 Ron) and 2 stroke oil. From what I've read, it'll haul 16x11 to 18x6 props with impunity. To top it off, the fuel will be cheap. As I am only a so so pilot, I like to fly these slow flying sport planes so the cheaper cost per flight will be much welcome. A glow 4 stroke nitro engine will cost something like $4 per flight in fuel. With one of these, it'll only be cents per flight. A bonus is the reliability and cooler running of gasoline engines.

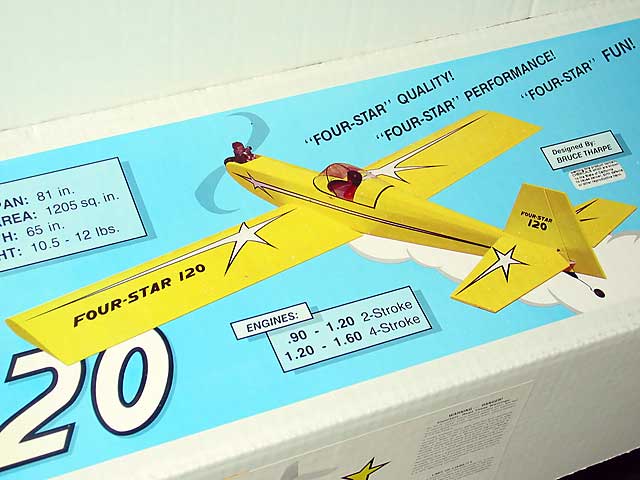

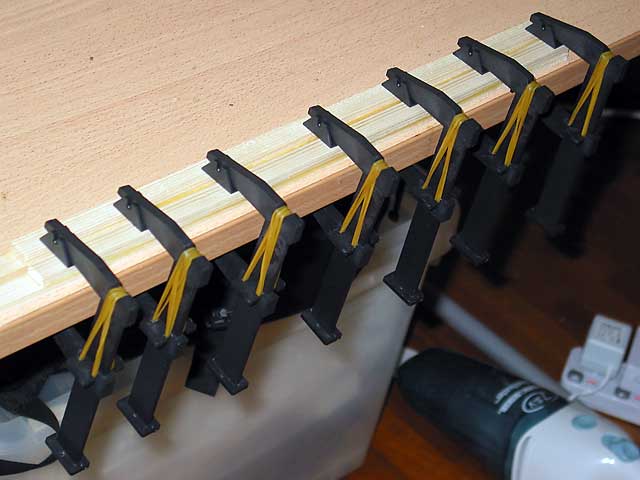

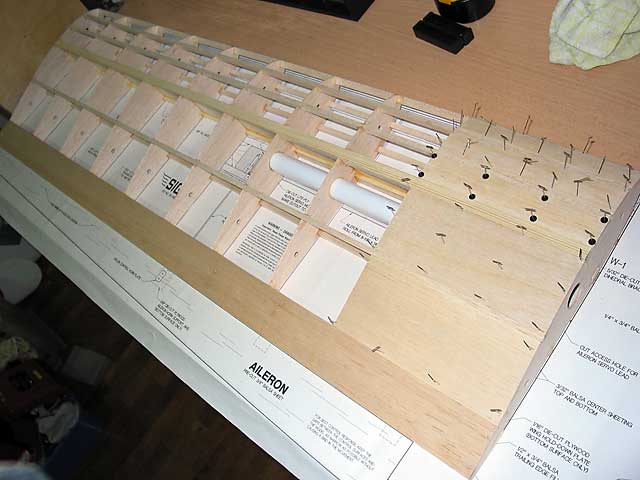

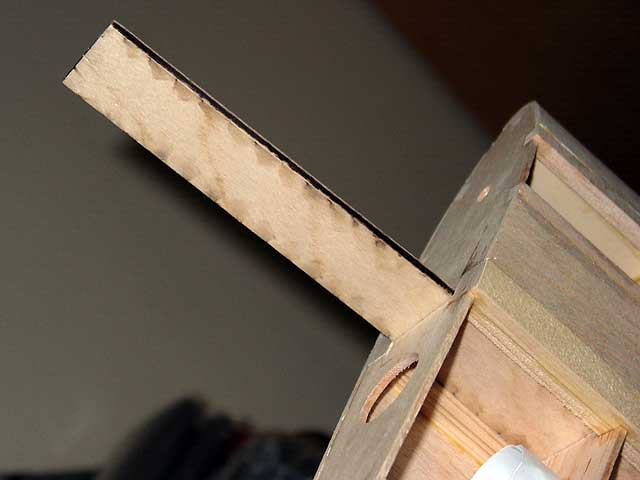

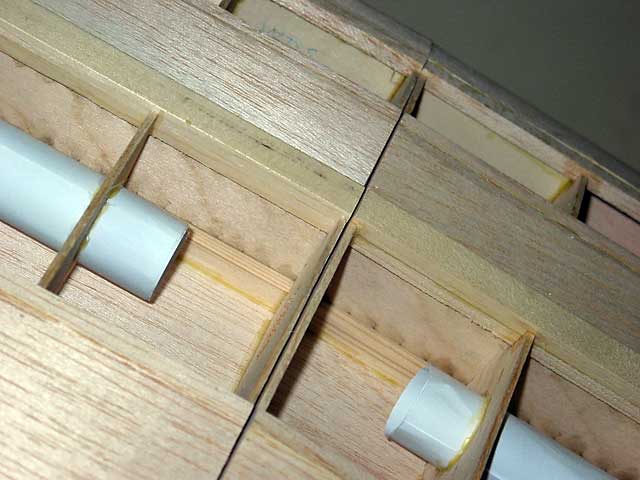

The Sig Four Forty series have developed a reputation for good flight characteristics and it looks like it'll be a fast building plane too. The box is filled with good quality balsa and laser cut parts look to be help in the building speed with its greater accuracy (die crushing seems now to be thing of the past). The kit is very complete with a several bags of hardware included down to hinges, engine mount and all screws and bolts. I will however be swapping out all the imperial bolts and replacing them with metric ones.

.

.

I'm going to start on this project on Monday.

The MVVS IFS 26 is a petrol engine. Runs on 40:1 gasoline (95 Ron) and 2 stroke oil. From what I've read, it'll haul 16x11 to 18x6 props with impunity. To top it off, the fuel will be cheap. As I am only a so so pilot, I like to fly these slow flying sport planes so the cheaper cost per flight will be much welcome. A glow 4 stroke nitro engine will cost something like $4 per flight in fuel. With one of these, it'll only be cents per flight. A bonus is the reliability and cooler running of gasoline engines.

The Sig Four Forty series have developed a reputation for good flight characteristics and it looks like it'll be a fast building plane too. The box is filled with good quality balsa and laser cut parts look to be help in the building speed with its greater accuracy (die crushing seems now to be thing of the past). The kit is very complete with a several bags of hardware included down to hinges, engine mount and all screws and bolts. I will however be swapping out all the imperial bolts and replacing them with metric ones.

.

.I'm going to start on this project on Monday.

Kway Chap Ong at Macpherson is super good too...let's go!!

Kway Chap Ong at Macpherson is super good too...let's go!!

... if not joking count me in leh... er... brandon got go must call me k?

... if not joking count me in leh... er... brandon got go must call me k?

Comment