Hello everyone! This is my first posting here. I'm glad to discover that there's a forum for Singapore fliers and other RC related hobbies.

I've been interested in model aviation since my secondary school days. Back then it was quite expensive to get into the hobby. It was fun designing, building and flying my own small RC planes. Since returning to the hobby again in 2004 after a hiatus of 5 years, I haven't built anything of my own design since 1999.

I am now fully into electric RC aviation and even dabbled with aerial photography using my 1st Estarter! My previous planes are the GWS-Estarter, ME-109, Tiger Moth, all decomissioned. Right now I have another spare Estarter and a Tucano of my own design.

I live at Ang Mo Kio and was one of the long time Bishan Flyers before they shut down the operation. The story goes that one of the flyers crashed his plane into a flat at Bishan scaring the living daylights of a toddler sitting in the living room. The window was smashed and you can imagine the fright and trauma the girl went through. After that incident and a newspaper report, the park permanently banned RC flying. Though it was a loss back then for RC flyers, I think it was a good move because the situation at Bishan was getting out of control, there was no regulation and no flying rules. There were many crashes though non-life threatening but still very serious. I still remember gas planes wings snapping in mid-air, spectacular helicopter crashes, one helicopter actually flew into the shelter with other flyers sitting underneath it, but they managed to run before the helicopter hit them. Though the atmosphere back then was friendly and everyone was helping each other out, there are still a few "rogue" flyers who fly recklessly.

With electric flying, the safety margin is increased slightly, but still flying electric planes can be dangerous. When I first started flying, I love flying my plane as high as it would go, but now with electrics and a longer flight time, I don't have to do that anymore, besides, I can't see the orientation properly anyway. Electric flying is really the way to go for land scarce Singapore.

Attached are the pictures of my Homebuilt Tucano, TigerMoth and ME-109 posed with my friend's Spitfire.

I've been interested in model aviation since my secondary school days. Back then it was quite expensive to get into the hobby. It was fun designing, building and flying my own small RC planes. Since returning to the hobby again in 2004 after a hiatus of 5 years, I haven't built anything of my own design since 1999.

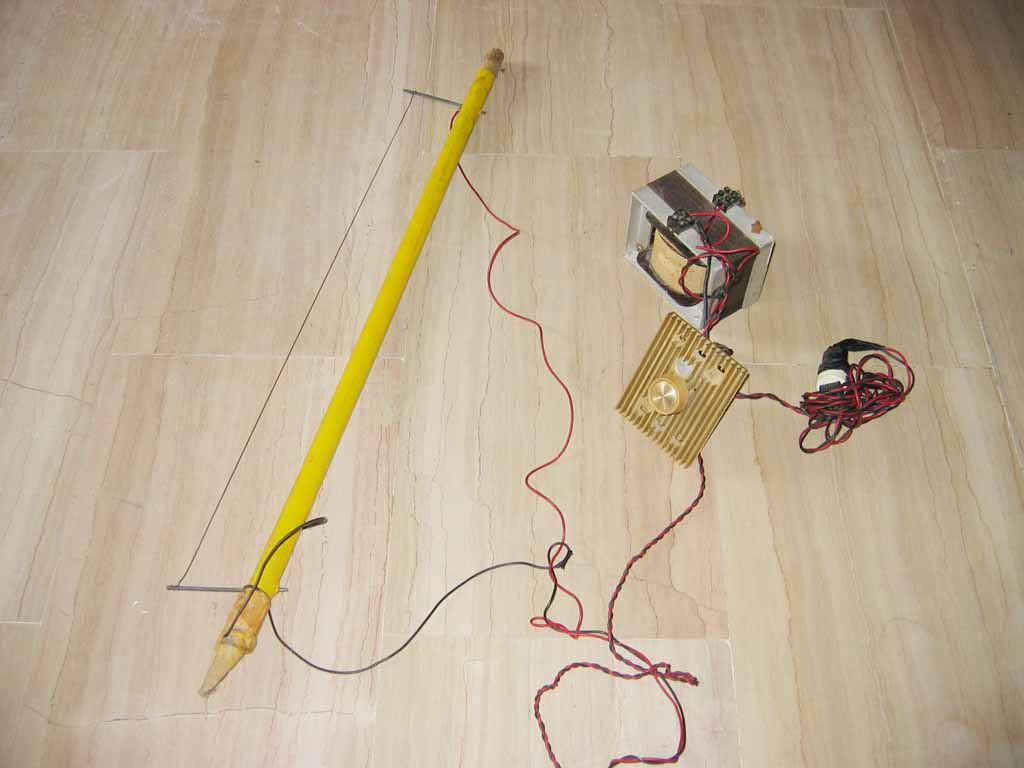

I am now fully into electric RC aviation and even dabbled with aerial photography using my 1st Estarter! My previous planes are the GWS-Estarter, ME-109, Tiger Moth, all decomissioned. Right now I have another spare Estarter and a Tucano of my own design.

I live at Ang Mo Kio and was one of the long time Bishan Flyers before they shut down the operation. The story goes that one of the flyers crashed his plane into a flat at Bishan scaring the living daylights of a toddler sitting in the living room. The window was smashed and you can imagine the fright and trauma the girl went through. After that incident and a newspaper report, the park permanently banned RC flying. Though it was a loss back then for RC flyers, I think it was a good move because the situation at Bishan was getting out of control, there was no regulation and no flying rules. There were many crashes though non-life threatening but still very serious. I still remember gas planes wings snapping in mid-air, spectacular helicopter crashes, one helicopter actually flew into the shelter with other flyers sitting underneath it, but they managed to run before the helicopter hit them. Though the atmosphere back then was friendly and everyone was helping each other out, there are still a few "rogue" flyers who fly recklessly.

With electric flying, the safety margin is increased slightly, but still flying electric planes can be dangerous. When I first started flying, I love flying my plane as high as it would go, but now with electrics and a longer flight time, I don't have to do that anymore, besides, I can't see the orientation properly anyway. Electric flying is really the way to go for land scarce Singapore.

Attached are the pictures of my Homebuilt Tucano, TigerMoth and ME-109 posed with my friend's Spitfire.

..... one word 'RESPECT'....

..... one word 'RESPECT'....

Comment