It has been some time since I did a build log. Recently, I was given the opportunity to build a pre-production Topsky 3 DLG. I'm always up for new models to build.

Topsky has impressed me as they have improved their line of DLGs rather rapidly. The quality has improved dramatically from their very first batch and the most recent one, the Topsky 3 looks rather impressive.

Here are some shots of the parts out of the box.

Topsky has impressed me as they have improved their line of DLGs rather rapidly. The quality has improved dramatically from their very first batch and the most recent one, the Topsky 3 looks rather impressive.

Here are some shots of the parts out of the box.

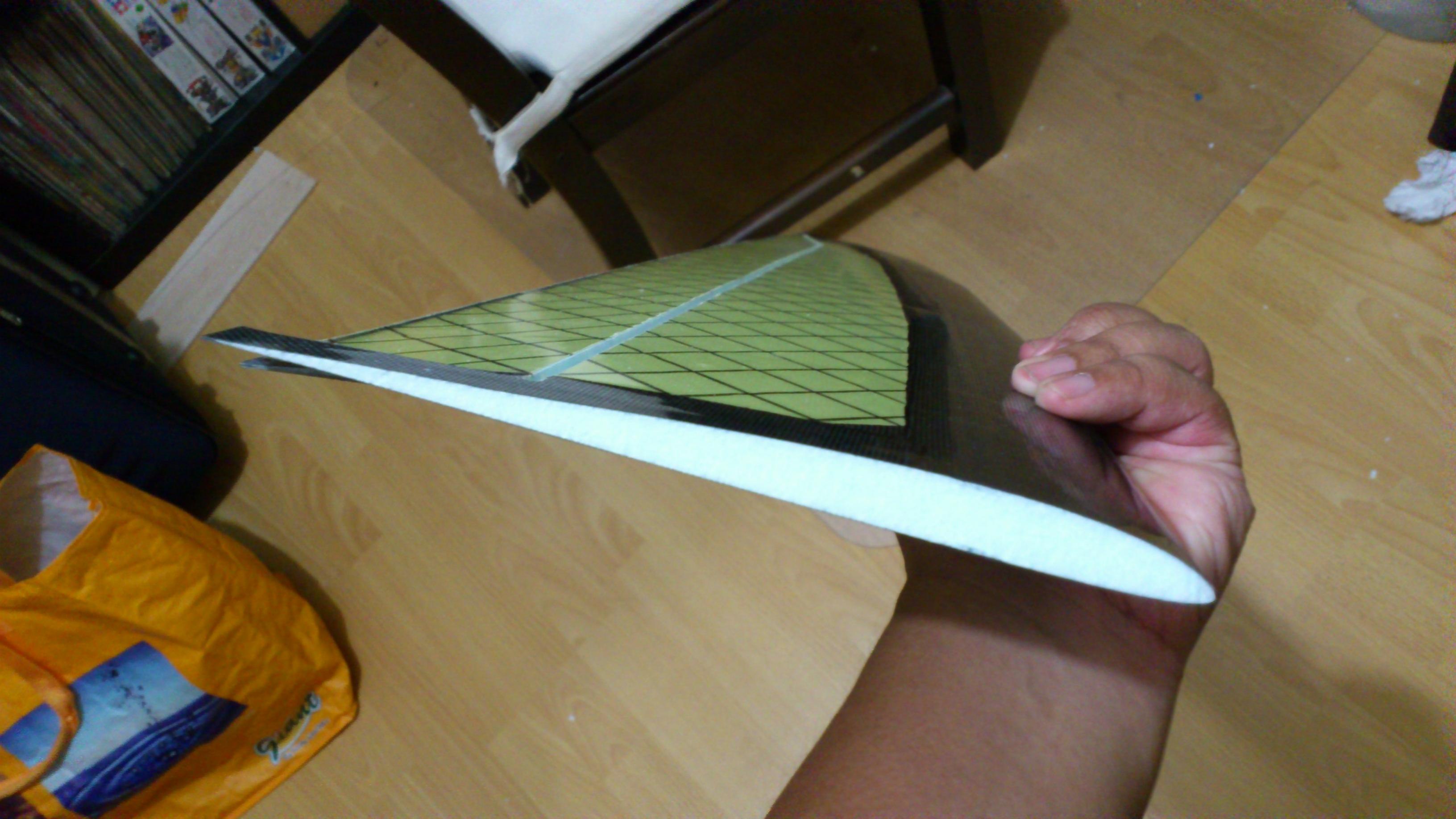

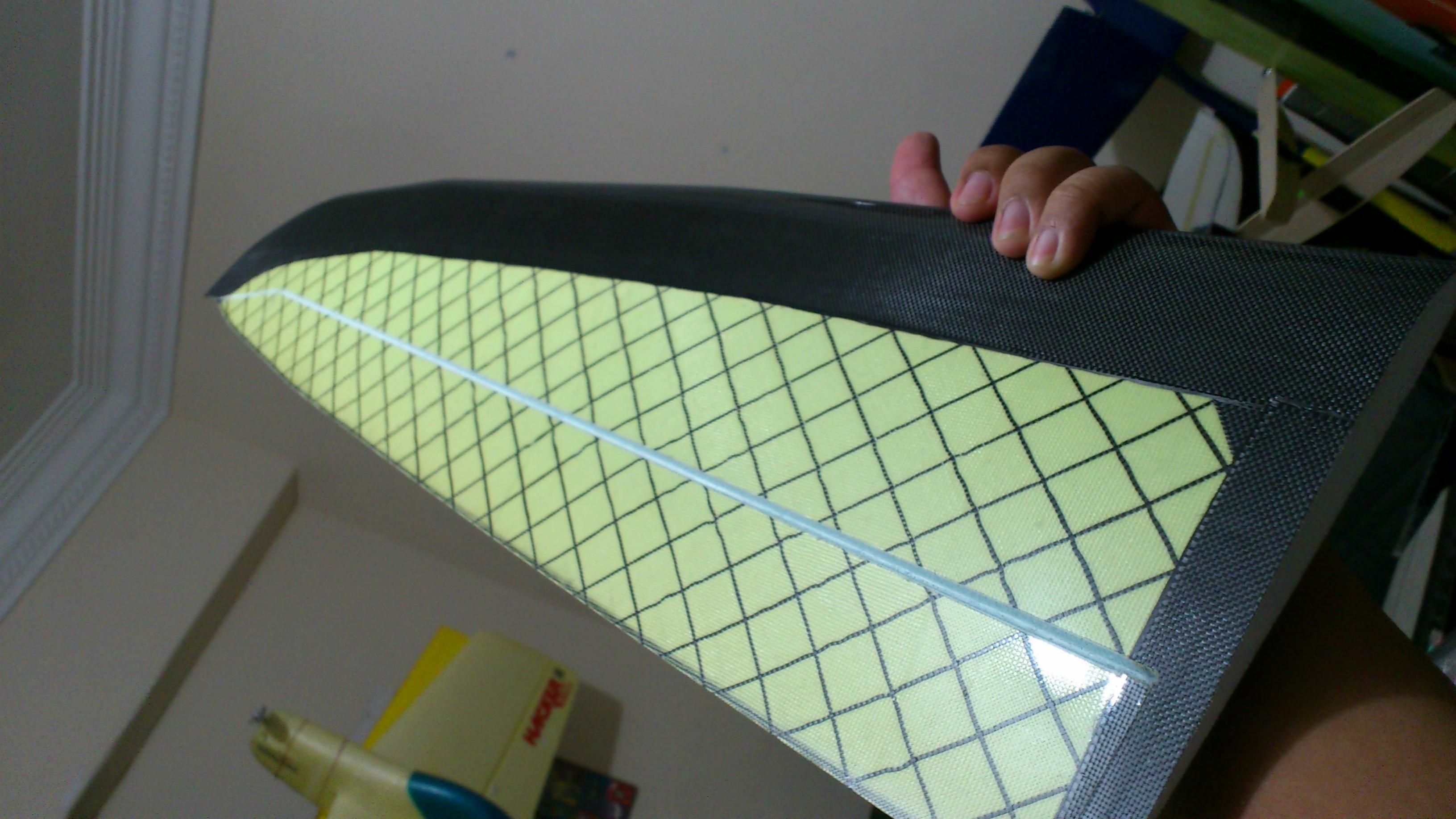

The shape at the wing tips bother me too. They seem sharp and I feel that it might cut the webbing in between my fingers on launch. I ended up sanding the tips on the launch blade side and now it has more than enough room to rotate all the way. I'm not to sure about the production runs of the TS3, but this one comes with a tough reflective wing bag.

The shape at the wing tips bother me too. They seem sharp and I feel that it might cut the webbing in between my fingers on launch. I ended up sanding the tips on the launch blade side and now it has more than enough room to rotate all the way. I'm not to sure about the production runs of the TS3, but this one comes with a tough reflective wing bag.

Comment