It's been a while since I posted my last build thread. Ever since I started working in a local Polytechnic, I have been building small electric trainers and hasn't build much models for myself.

While I went down to Fook Hai this afternoon to look for a wing joiner tube for my upcoming scale glider scratch build project, I suddenly remembered that I was looking at the mini Topsky in the internet lately. Recently, I have been trying out thermalling at my school field with my Predator 2 DLG, I bought from SC years ago.

It was only yesterday that the local contractor started to cordon off some parts of the school field for some upcoming expansion projects. Suddenly, it came to my mind that I may need a smaller DLG to fly at whatever spaces available within the school, and a mini or micro DLG seems like something I should explore.

Back to the shopping @ FH this afternoon. After walking into SHS, I was looking around the shop, before I was shown the few kits of the Mini Topsky. The one with the green fuselage I saw, is very nice. However, I settled on the orange fuselage pod as it should be more visible against my schools greenery background.

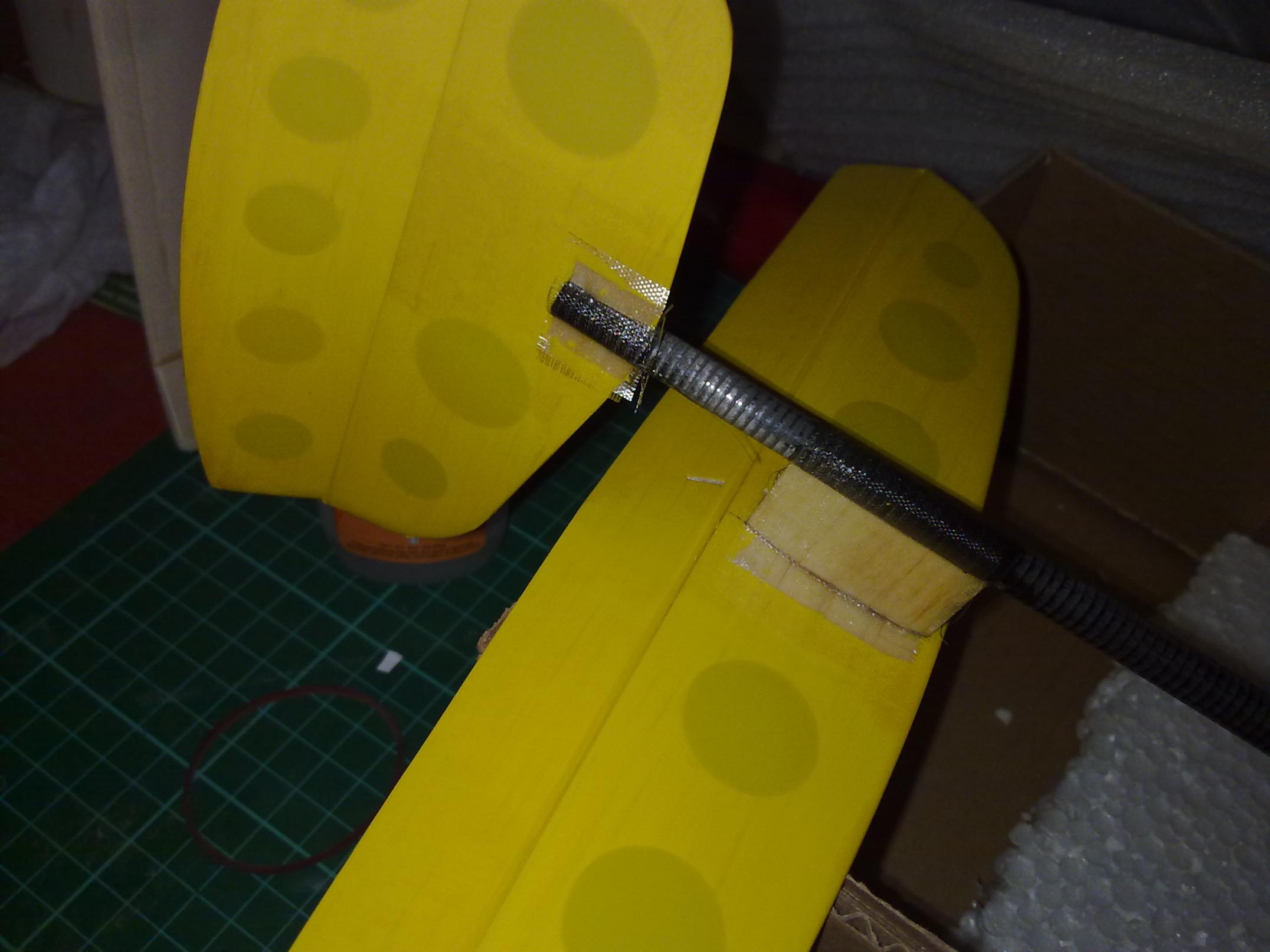

After reaching school, I immediately shown it to my colleague to impressed them with the worksmanship of the kit. Of course, it is far cry compared to the high-end European DLGs, but for a scratchbuilder point of view, the worksmanship is still admirable.

While I went down to Fook Hai this afternoon to look for a wing joiner tube for my upcoming scale glider scratch build project, I suddenly remembered that I was looking at the mini Topsky in the internet lately. Recently, I have been trying out thermalling at my school field with my Predator 2 DLG, I bought from SC years ago.

It was only yesterday that the local contractor started to cordon off some parts of the school field for some upcoming expansion projects. Suddenly, it came to my mind that I may need a smaller DLG to fly at whatever spaces available within the school, and a mini or micro DLG seems like something I should explore.

Back to the shopping @ FH this afternoon. After walking into SHS, I was looking around the shop, before I was shown the few kits of the Mini Topsky. The one with the green fuselage I saw, is very nice. However, I settled on the orange fuselage pod as it should be more visible against my schools greenery background.

After reaching school, I immediately shown it to my colleague to impressed them with the worksmanship of the kit. Of course, it is far cry compared to the high-end European DLGs, but for a scratchbuilder point of view, the worksmanship is still admirable.

Comment