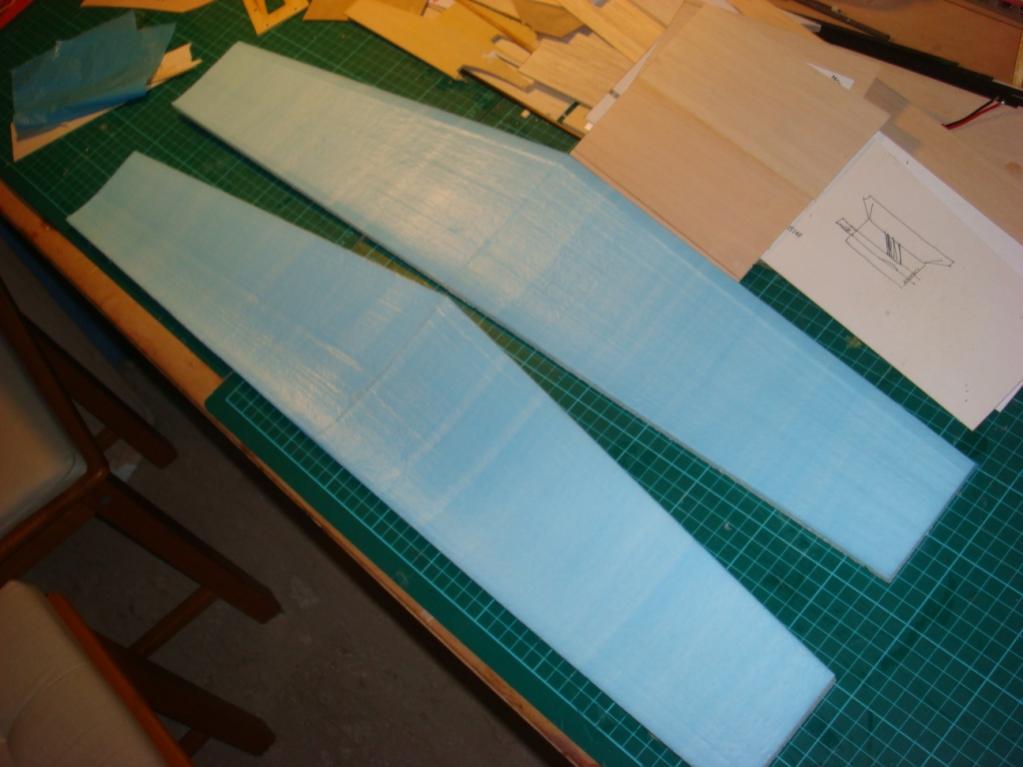

With some showing interest in my old Deceiver pylon racer ;http://www.daddyhobby.com/forum/show...light=deceiver, I am starting this construction thread on my re-designed T-tailed version of the Deceiver, which I called it the "Swindler".

Folks who are building the Deceiver can still benefit from this thread as the only main difference will just be the the tail design. The most crucial part, which happens to be the wings construction, os the same for both.

By the way, the original Deceiver was designed for brushed Speed 400 motors with 7-8 cell Nimh or Nicd batteries. Thier input power is around 100watts but the average efficiencies of 50% means that only 50watt of output power is being yield.

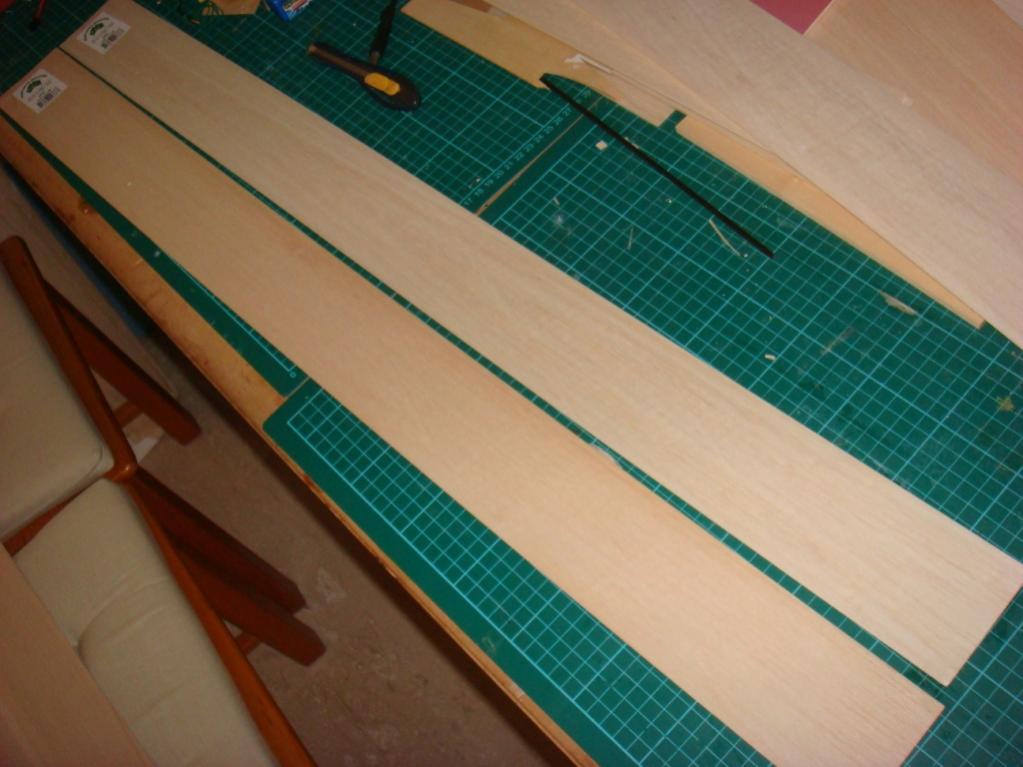

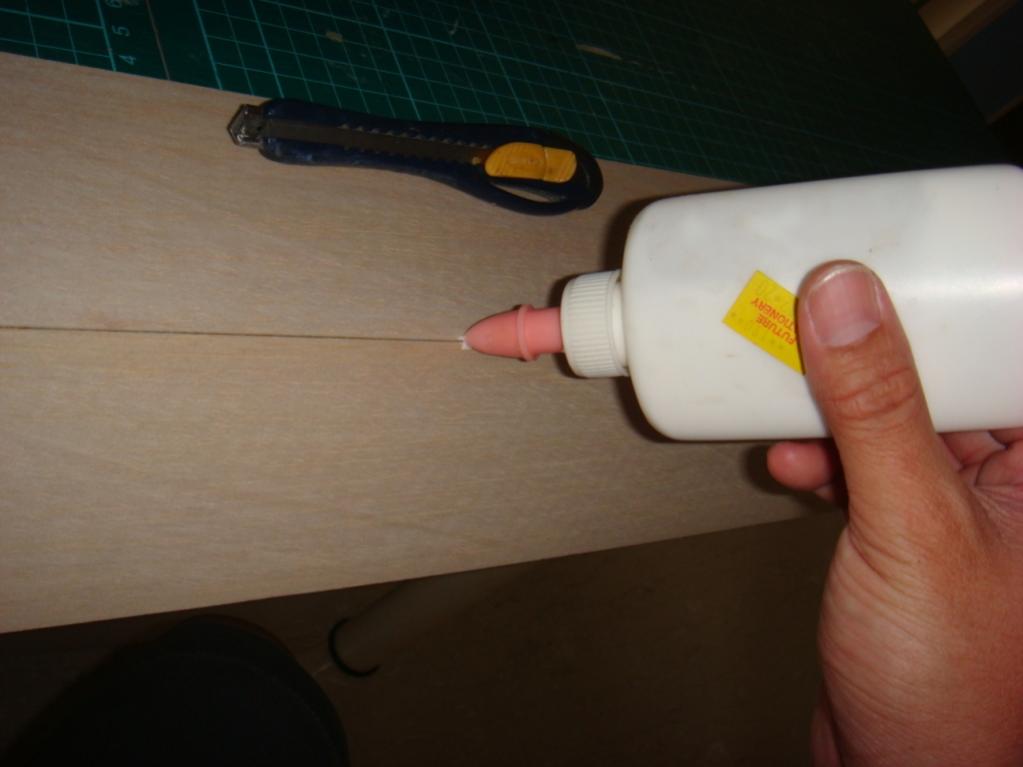

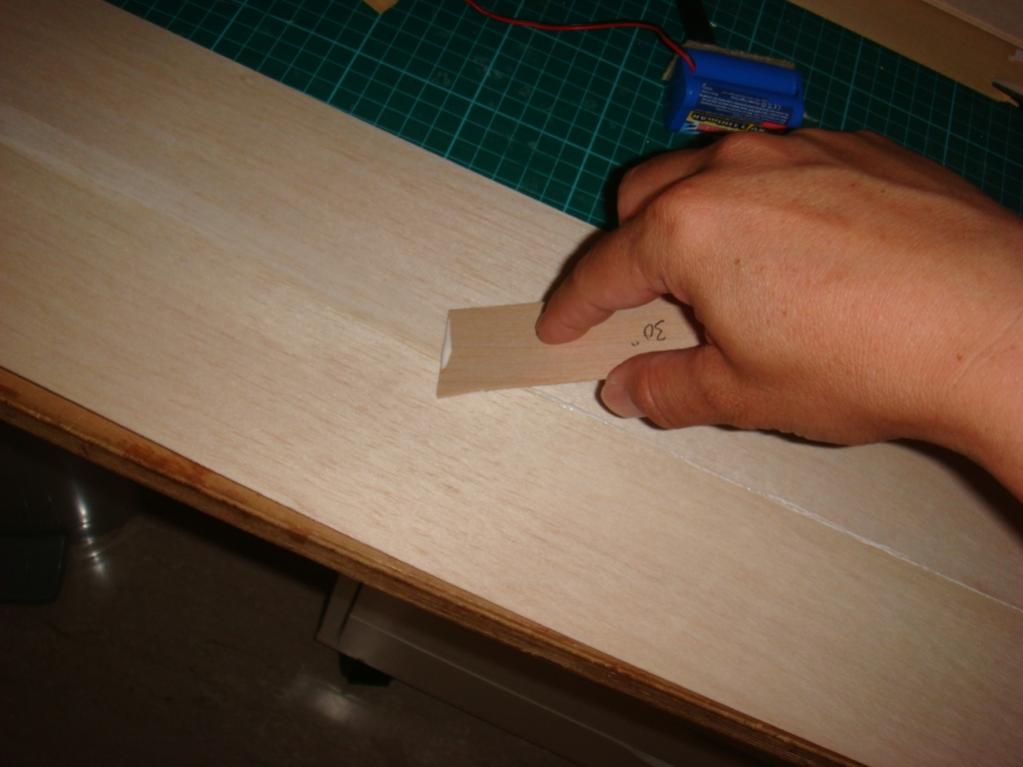

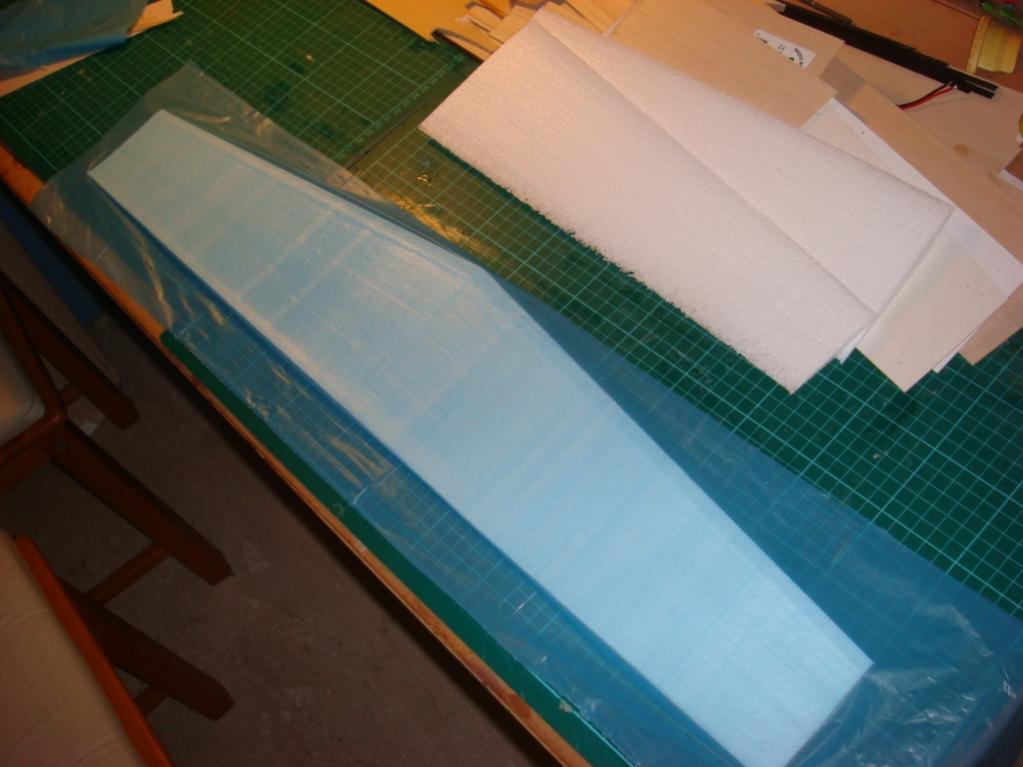

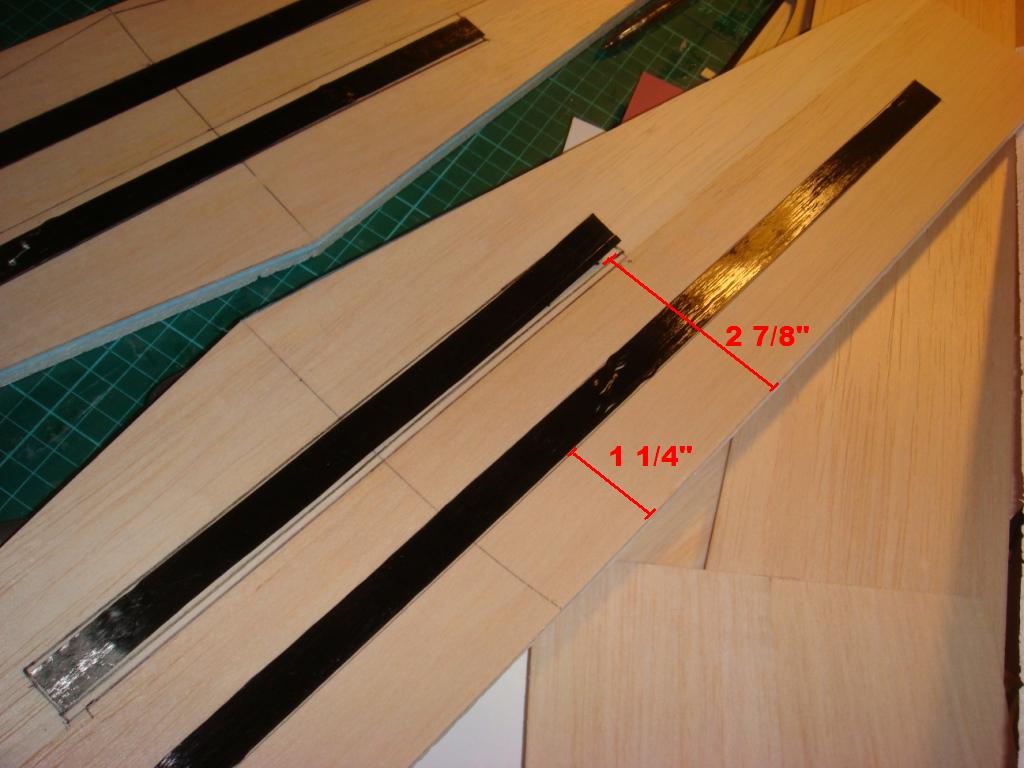

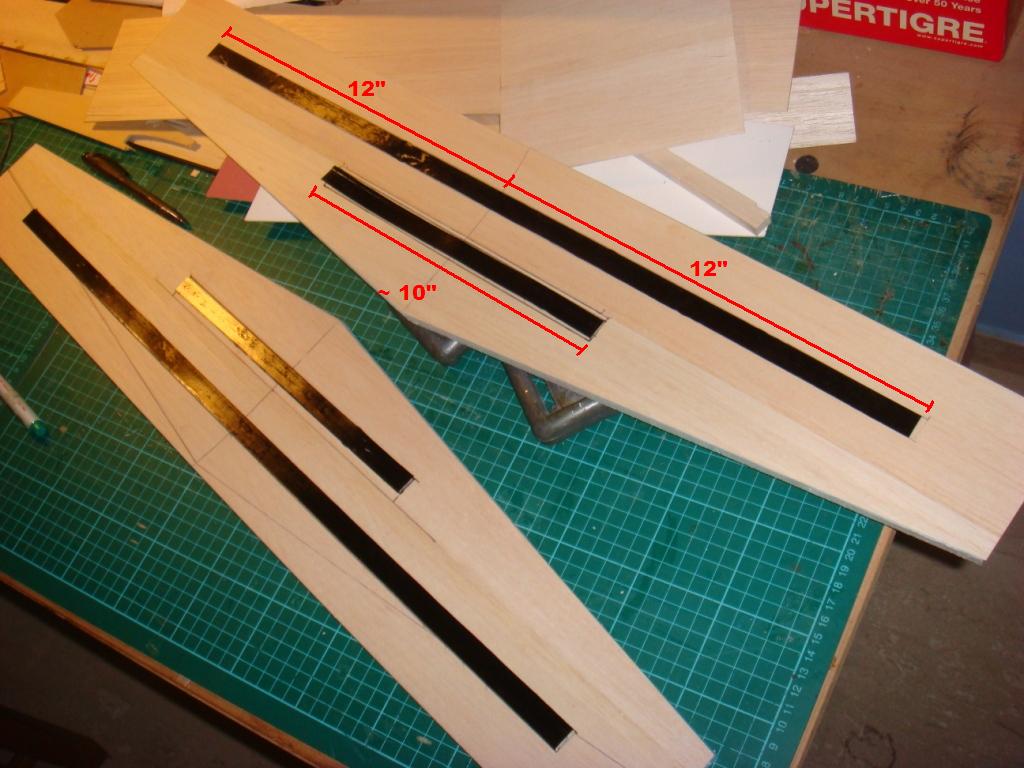

As the modern brushless motors have around 75% efficiencies, plus the input power can easily doubled or tripled, the airframe design needs significant beefing up. I even managed to fold the wings of the first model on brushed motor, and so needless to say, a lot more attention has to be paid during the wing construction.

Folks who are building the Deceiver can still benefit from this thread as the only main difference will just be the the tail design. The most crucial part, which happens to be the wings construction, os the same for both.

By the way, the original Deceiver was designed for brushed Speed 400 motors with 7-8 cell Nimh or Nicd batteries. Thier input power is around 100watts but the average efficiencies of 50% means that only 50watt of output power is being yield.

As the modern brushless motors have around 75% efficiencies, plus the input power can easily doubled or tripled, the airframe design needs significant beefing up. I even managed to fold the wings of the first model on brushed motor, and so needless to say, a lot more attention has to be paid during the wing construction.

Comment