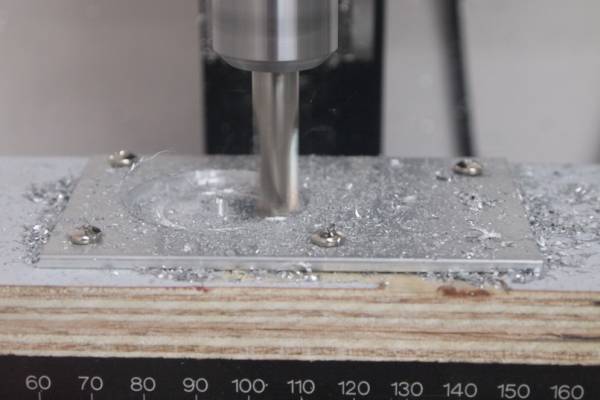

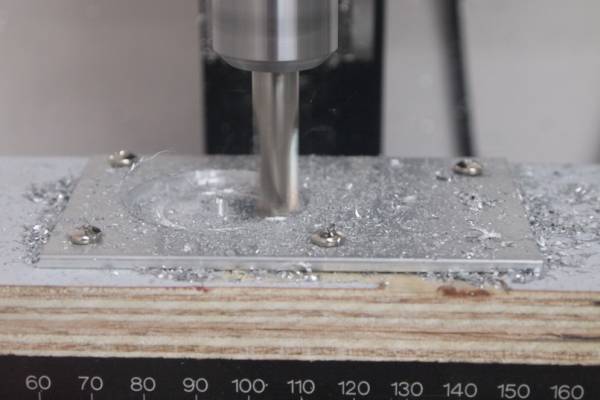

Way before we bring in the Proxxon MF 70 Micro Mill, had read many things about converting it to CNC. Did a search, most converted system use for engraving, CNC of wood panel, CNC PCB and pocketing of electronic panel. All these are quite an issue if you use manual system.

The moment the machine arrived, stripped bare the entire system to have access to the leadscrew and do necessary modification.

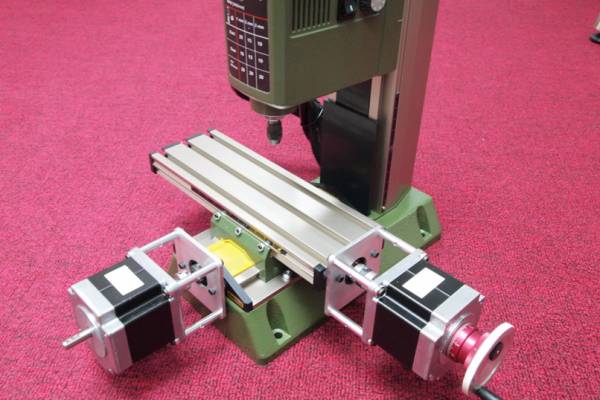

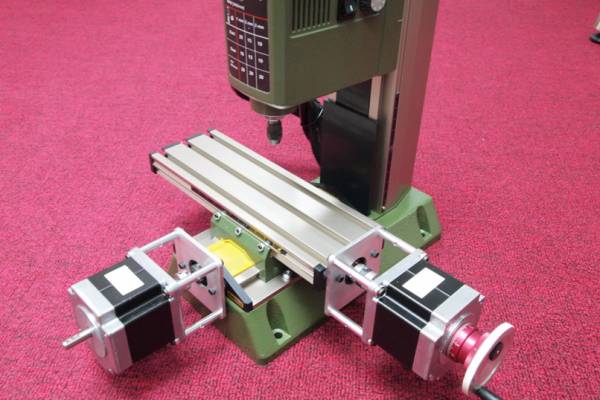

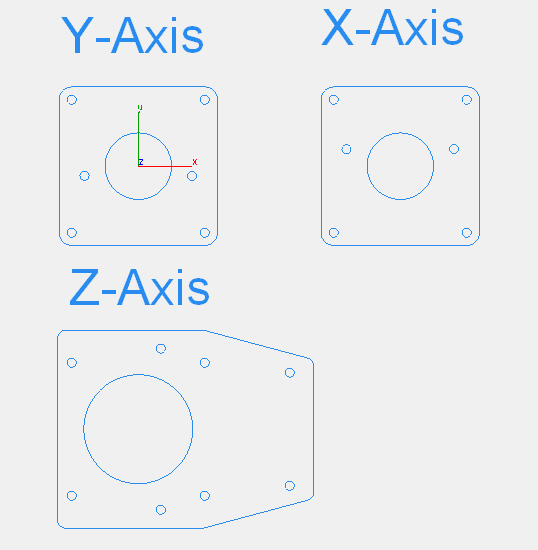

I am sorry, was too anxious till I forgotten about taking pics. Anyway, heres a pic of the Sherline CNC machine which was used to fabricate the mounting.

Machine is about 80% complete, just need to do some more light machining to get the coupling in place. Then it will be completed.

A pic with the iPhone on it to give you an idea the size of this machine.

Cheers

Mike

The moment the machine arrived, stripped bare the entire system to have access to the leadscrew and do necessary modification.

I am sorry, was too anxious till I forgotten about taking pics. Anyway, heres a pic of the Sherline CNC machine which was used to fabricate the mounting.

Machine is about 80% complete, just need to do some more light machining to get the coupling in place. Then it will be completed.

A pic with the iPhone on it to give you an idea the size of this machine.

Cheers

Mike

Jyheli also told me he needs some CNC work.

Jyheli also told me he needs some CNC work.

Comment