Hi guys. This is my lastest scratch build project so far. And i must say this is one my longest project i ever planned + building. Even i set aside 5hours a day ,i took nearly 2 weeks to complete.

My goal:

-is to build a f-16 weighing under 700grams

-Build it before 9th august (national day)

-Make it as realistic as possible (looks as real as a f-16)

-I'm going for maneuverability rather then speed

-Lastly, paint a RSAF blackknight scheme on it!

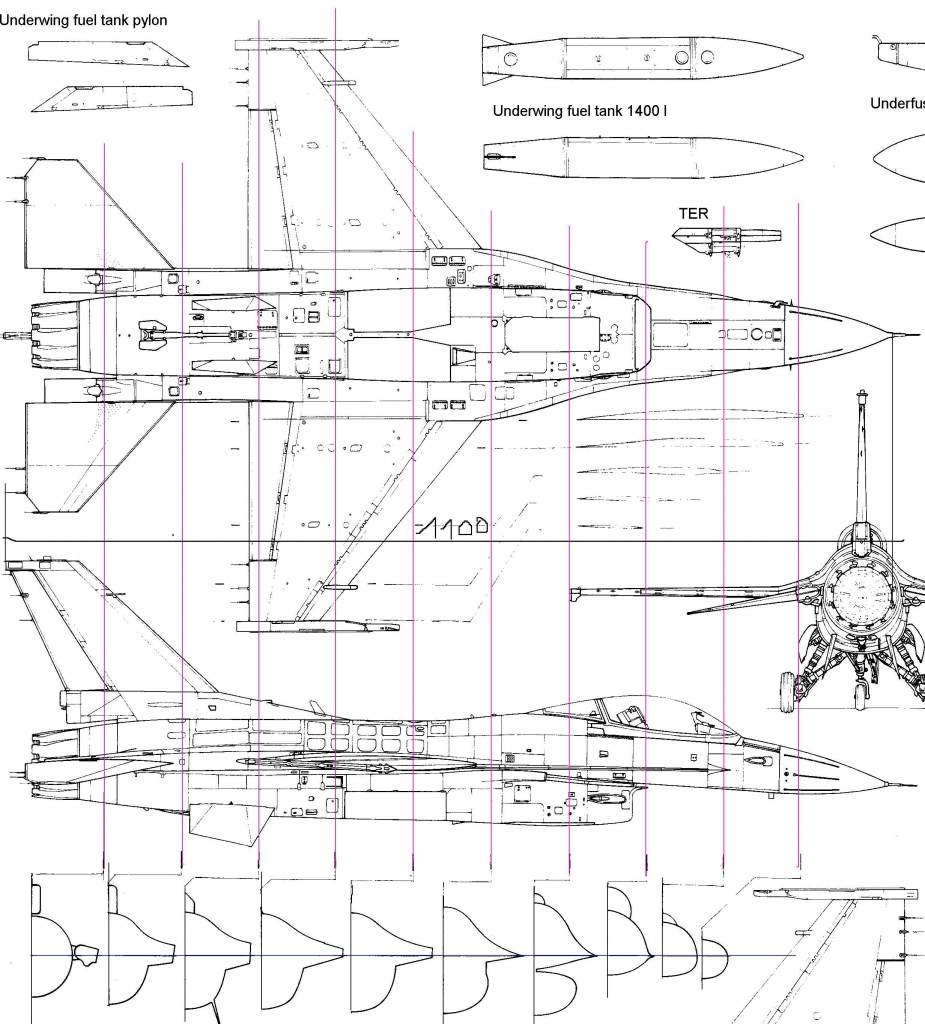

Firstly, I start off by finding f-16 plans on the web...which i'm unable to do so. Even though parkjets has 4 F-16 plans , They require hot water foam bending which requires 6mm depron. (i have no experience in that) Futhermore i'm using blue foam for this build.

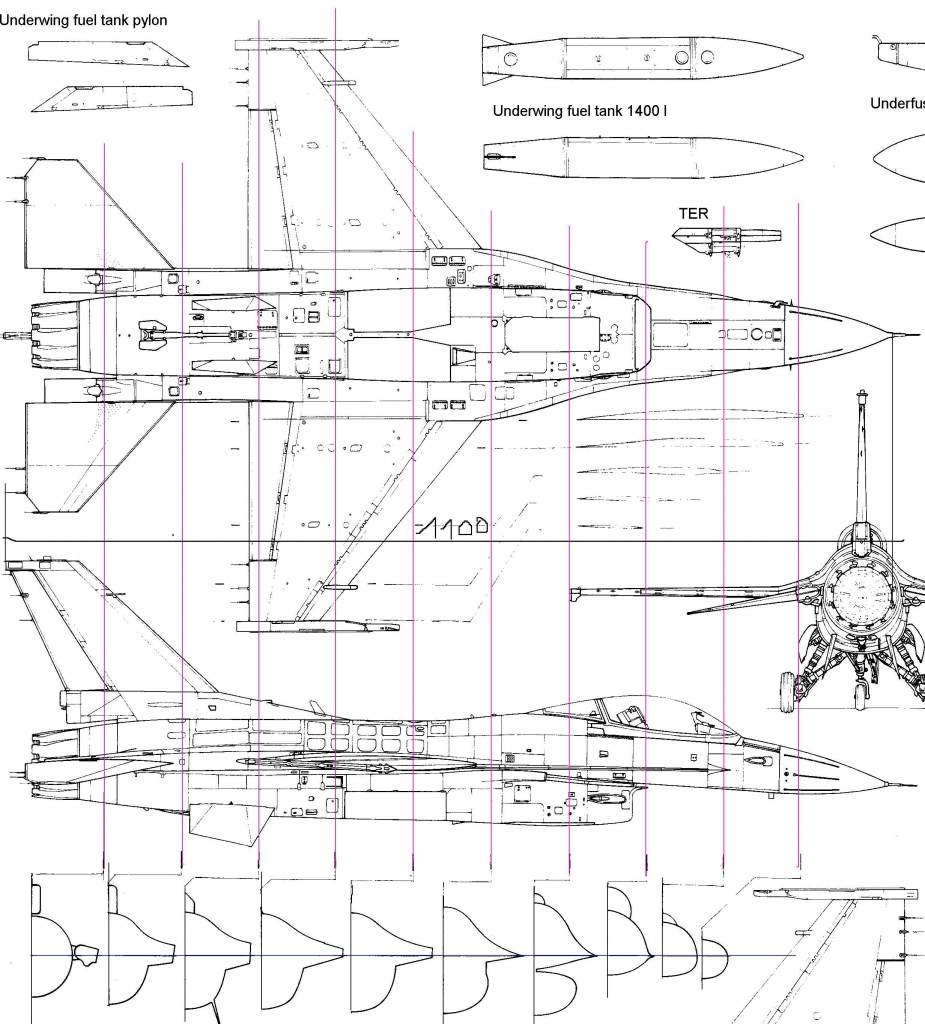

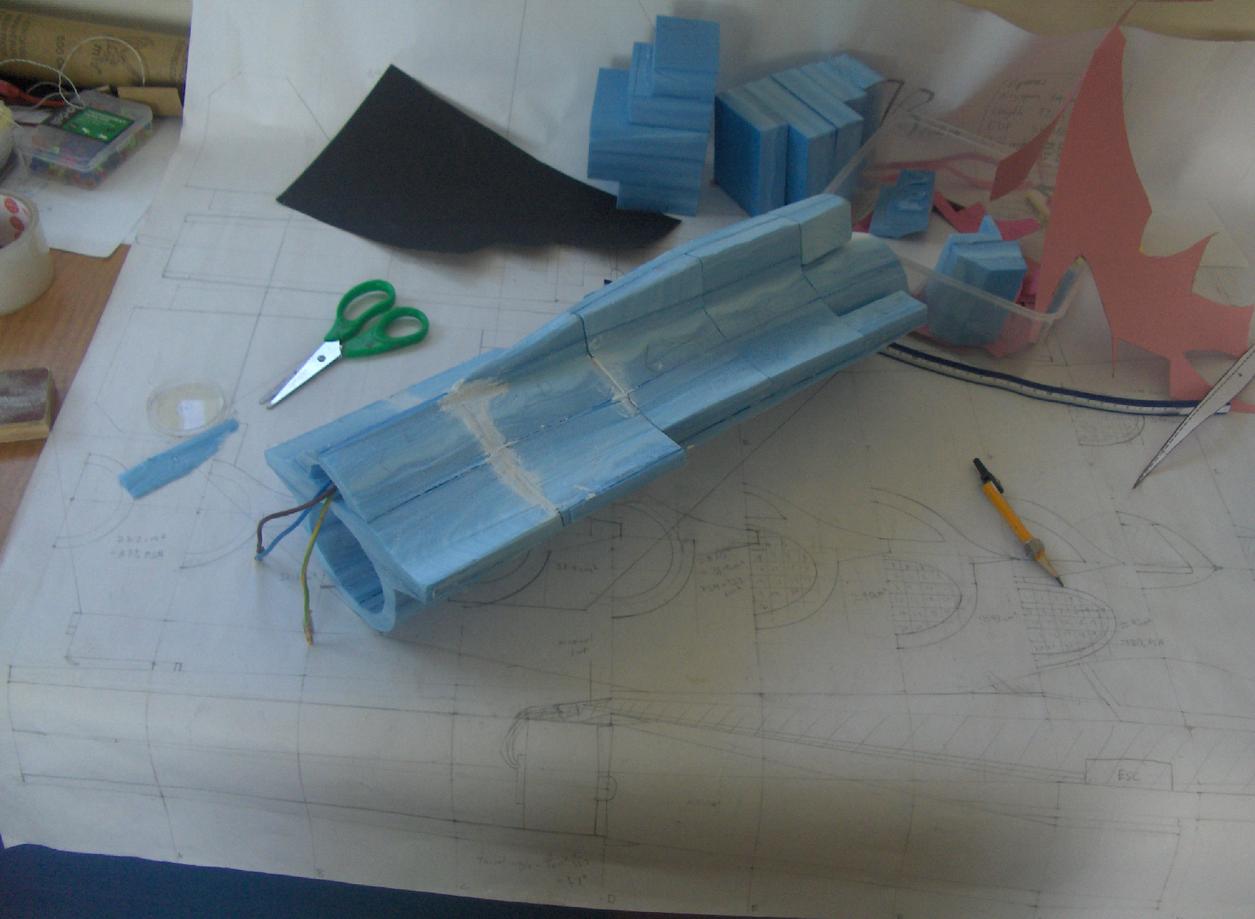

I Downloaded a 3 plan-view from the net... which is supposingly the REAL f-16 build plan. The plan came out pretty small from my printer so i had to rescale it up 5times by drawing on a piece of majong paper. Which probably took me 5days i draw...tons of calculation especially calculating each cross-sectional area of the EDF with decreasing area from intake to exhuast. Big headache.

I use the rule of thumb 120% FSA for intake and 90%FSA for exhuast.

My goal:

-is to build a f-16 weighing under 700grams

-Build it before 9th august (national day)

-Make it as realistic as possible (looks as real as a f-16)

-I'm going for maneuverability rather then speed

-Lastly, paint a RSAF blackknight scheme on it!

Firstly, I start off by finding f-16 plans on the web...which i'm unable to do so. Even though parkjets has 4 F-16 plans , They require hot water foam bending which requires 6mm depron. (i have no experience in that) Futhermore i'm using blue foam for this build.

I Downloaded a 3 plan-view from the net... which is supposingly the REAL f-16 build plan. The plan came out pretty small from my printer so i had to rescale it up 5times by drawing on a piece of majong paper. Which probably took me 5days i draw...tons of calculation especially calculating each cross-sectional area of the EDF with decreasing area from intake to exhuast. Big headache.

I use the rule of thumb 120% FSA for intake and 90%FSA for exhuast.

)

)

..probably thanks to the clean airfoil and fuselage.

..probably thanks to the clean airfoil and fuselage.

Comment