Hi all

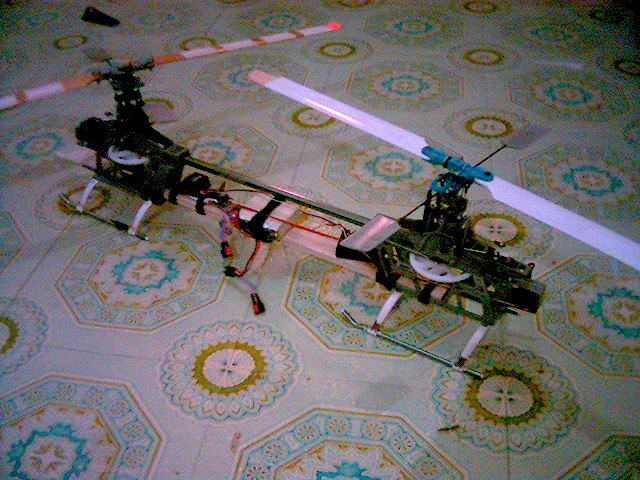

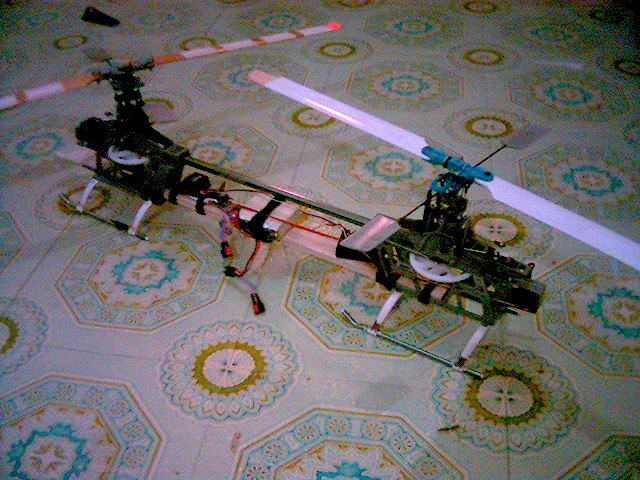

Just finish fixing and trying my very first Tandem (also known as Chinook) TRex. This is very first prototype.

Result:

Not good because notice that even both side (Front and Rear) are using same TRex main gear and tail pulley, somehow the ratio division is not equal. With that, after a while, the both frontal and back rotor HIT EACH Other. If both front and rear rotor spin in equal speed (Which should be because it is driven by a single motor), it should not hit each other.

Alot of mixing is require to make this fellow works. Might require gyro for Elevator movement. Currently in the picture, there is a GY240 but it is turn off and it just act as wire extension.

Wasted one pair of Wooden 315mm blades due to blade hitting. Will try to make them spin in totally equal speed before can try again.

SH.

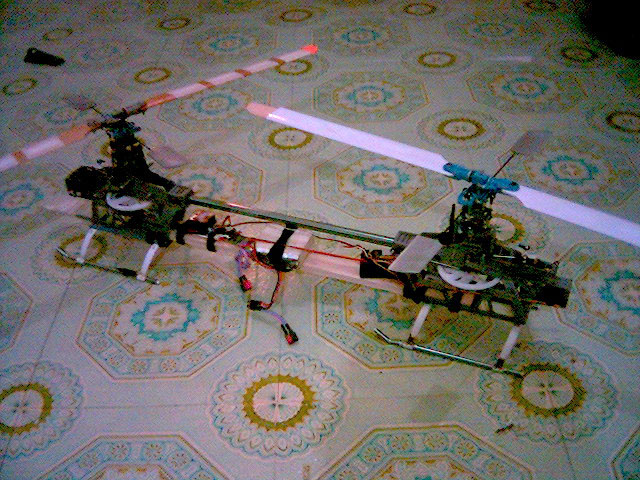

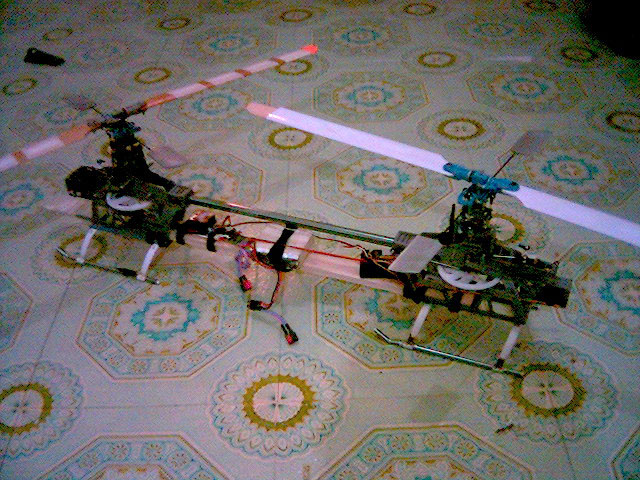

Just finish fixing and trying my very first Tandem (also known as Chinook) TRex. This is very first prototype.

Result:

Not good because notice that even both side (Front and Rear) are using same TRex main gear and tail pulley, somehow the ratio division is not equal. With that, after a while, the both frontal and back rotor HIT EACH Other. If both front and rear rotor spin in equal speed (Which should be because it is driven by a single motor), it should not hit each other.

Alot of mixing is require to make this fellow works. Might require gyro for Elevator movement. Currently in the picture, there is a GY240 but it is turn off and it just act as wire extension.

Wasted one pair of Wooden 315mm blades due to blade hitting. Will try to make them spin in totally equal speed before can try again.

SH.

Comment