Originally posted by Adrianli

View Post

Mfr made coupler usually via boring / using precision drill / reamer.

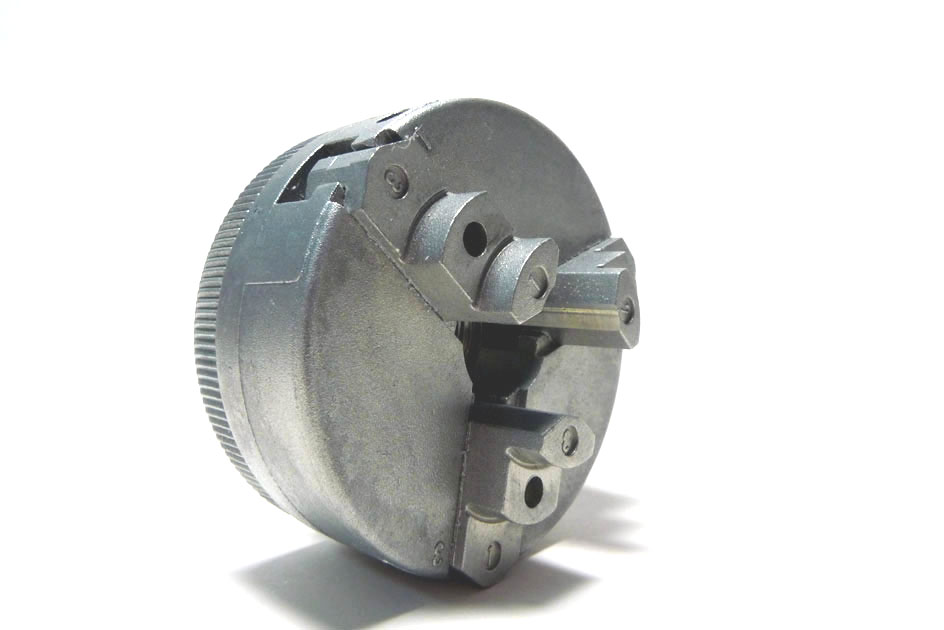

In case of home fabrication of 8mm hole, only lathe doable to ensure the concentricity especially u are driving at high rpm. We will drill a max hole size of the lathe, then using a boring tool and slowly open up the hole. Along the way will trial fit with the shaft. Boring bit by bit will ensure a sui sui fitting, using a 8mm drill bit might result in la KOPI

If die die want to use a 8mm drill also possible. We can provide shank reducing service at a small fee. Meaning using industrial machine to precisely grind down the 8mm shank to 6mm shank.

Mike

Comment