machine shop services offer

Hello all:

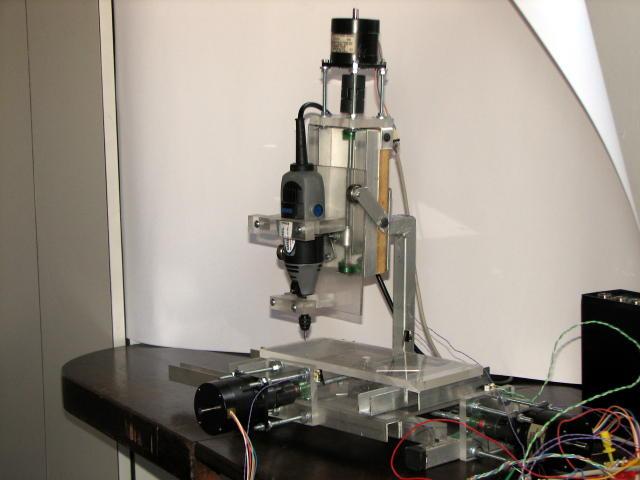

Our machine shop is offering a special services to all CNC home builder. Just send us the parts that you have difficult of making either in cad files or starch drawing ,and we will quote our best prices at

no time..... For more information

please contact us at the following E-mail:

tclcpw@gmail.com

P.S. For your information we had just finish building the ER-16 tool holder, a close step to AUTO tool change...

Hello all:

Our machine shop is offering a special services to all CNC home builder. Just send us the parts that you have difficult of making either in cad files or starch drawing ,and we will quote our best prices at

no time..... For more information

please contact us at the following E-mail:

tclcpw@gmail.com

P.S. For your information we had just finish building the ER-16 tool holder, a close step to AUTO tool change...

Comment